TM 5-3805-262-34

3-12. AIR BRAKE SYSTEM MAINTENANCE (CONT)

e. Air Compressor Assembly (Cont).

(2) Cylinder

REASSEMBLY (SHEET

Block and Crankcase (Cont).

1 OF 4)

Wear heat resistant gloves

burning your hands. If you

immediately.

(a)

(b)

(c)

(d)

(e)

(f)

(g)

(h)

(i)

(j)

(k)

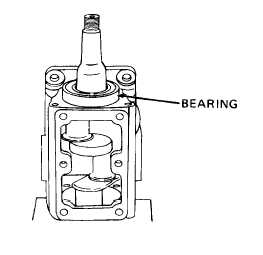

Heat bearing (26) in

Using heat resistant

when working with heated parts to prevent

are burned by heated parts obtain medical aid

oven to 250 degrees F.

gloves,

install

bearing (26) on crankshaft (27) so

that part number on bearing is facing

up. Make sure inner race on bearing

is firmly seated against shoulder of

crankshaft. Use hydraulic press and

2-1/2 inches inside diameter sleeve

to install bearing if necessary.

Put crankcase (30) in hydraulic press.

Install crankshaft (27) and bearing

(26), starting bearing into crankcase.

Using hydraulic press, press bearing

(26) into crankcase (30) to same depth

recorded during disassembly.

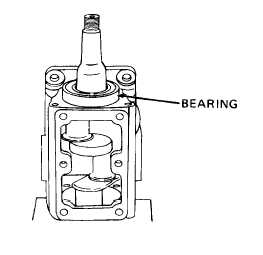

Apply non-hardening sealant to outside diameter of new seal (24).

Using hydraulic press, press new seal (24) into bearing cap (23). Use

2-1/8 inches diameter rod. Don’t use too much pressure to prevent damag-

ing seal and bearing cap.

Position new gasket (25) on crankcase (30).

Install bearing cap (23) using four capscrews (22). Alternately tighten

capscrews to 120 to 160 lb-in.

Position new gasket (21) on crankcase (30).

Lubricate bore of end cover (20) with clean lubricating oil.

Install end cover (20) using four capscrews (19).

3-486