TM 5-3805-262-34

REASSEMBLY (SHEET 2 OF 4)

NOTE

If cylinder block (2) bores were honed to next oversize diameter,

install oversize pistons (18) and ring sets (13 thru 15).

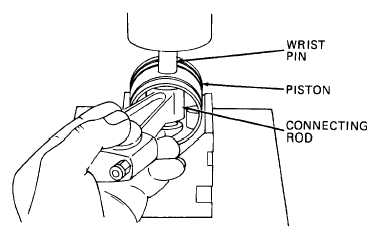

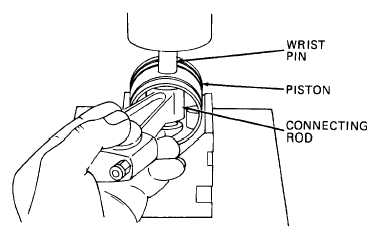

(l) Put V-block in hydraulic press and position piston (18) on V-block with

wrist pin hole upward. Start wrist pin (17) in piston. Wrist pin must be

straight. Press wrist pin into piston until associated connecting rod

(12) can be started onto wrist pin.

(m) Start associated connecting rod (12) on wrist pin (17) inside piston

(18). Press wrist pin through bore in connecting rod into opposite side

of piston. Using 3/8 inch diameter rod, center wrist pin in piston.

(n) Repeat steps (1) and (m) above to assemble remaining piston (18) to

connecting rod (12).

NOTE

If cylinder block (2) bores were honed to next oversize diameter,

install oversize ring sets (13 thru 15).

(o) Install new oil ring (14) in bottom groove on piston (18).

(p) Install new expander ring (15) in bottom groove on piston (18). Ends of

expander ring must make contact, not overlap, and be 90 degrees from

ends of oil ring (14).

(q) Install other oil ring (14) in bottom groove on piston (18), expander

ring (15) between two oil rings. Ends of two oil rings must be 180

degrees apart.

3-489