TM 5-3805-262-34

2-5. FUEL SYSTEM TROUBLESHOOTING

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

1. FUEL INJECTION PUMP NOT OPERATING PROPERLY.

Step 1.

Remove fuel injection pump from engine (page 3-136).

Dry cleaning solvent P-D-680 used to clean parts is toxic and flammable.

Wear protective goggles and gloves and use only in a well ventilated

area. Avoid contact with skin, eyes and clothes and don’t breathe

vapors . Do not use near open flame or excessive heat and don-t smoke

when using it. Failure to do so could cause serious injury. If you be-

come dizzy while using cleaning solvent, get fresh air and medical

attention immediately. If contact with skin or clothes is made, flush

with large amounts of water.

If contact with eyes is made, wash eyes

with water and get medical aid immediately.

Using clean cloth moistened

with cleaning solvent, thor-

oughly clean exterior of

fuel injection pump. Dry us-

ing clean cloths.

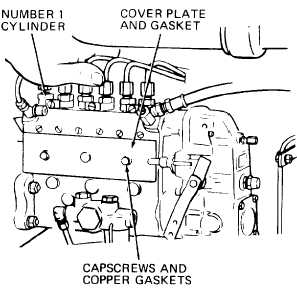

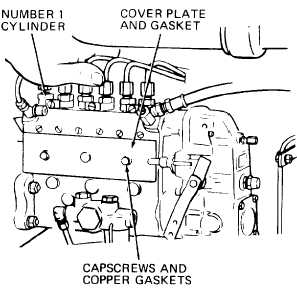

Remove two capscrews and

copper gaskets, then remove

cover plate and gasket.

Allow oil to drain from fuel

injection pump.

Rotate camshaft in counter-

clockwise direction as

viewed from drive end while

checking that roller tap-

pets, springs, and plungers

operate in firing order se-

quence 1-5-3-6-2-4.

a.

b.

If roller tappets,

springs, and plungers

operate in firing order

sequence, go to step 2

below.

If roller tappets, springs, and plungers do not operate in fir-

ing order sequence, problem could be damaged camshaft or cam-

shaft is installed incorrectly. Disassemble fuel injection pump

(page 3-140) and check cause.

2-47