TM 5-3805-262-34

3-21. CHECKS AND ADJUSTMENTS AND FLOWMETER TESTS

Check (SHEET 1 OF 2). This task covers

checking of main relief valve pressure setting.

TOOLS: No. 1 Common Organizational Maintenance Tool Kit

Slip joint pliers

Pressure gage, zero to 3000 psi range

MATERIALS/PARTS: Clean cloths (Appendix C, item 1)

Cleaning solvent P-D-680 (Appendix C, item 2)

Dry cleaning solvent P-D-680 used to clean parts is toxic and flammable.

Wear protective goggles and gloves and use only in a well ventilated

area. Avoid contact with skin, eyes and clothes and don’t breathe

vapors. Do not use near open flame or excessive heat and don’t smoke

when using it. Failure to do so could cause serious injury. If you

become dizzy while using cleaning solvent, get fresh air and medical

attention immediately. If contact with skin or clothes is made, flush

with large amounts of water. If contact with eyes is made, wash eyes

with water and get medical aid immediately.

(1)

(2)

(3)

(4)

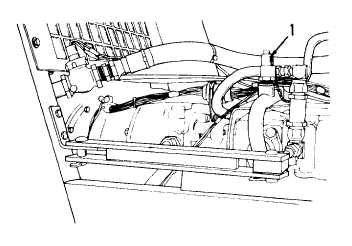

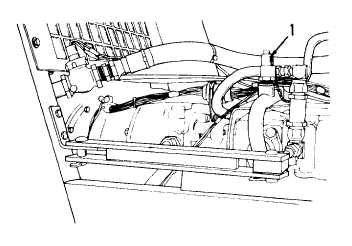

Using clean cloth moistened

with cleaning solvent P-D-

680, clean all dirt and

grease from quick disconnect

coupling (1) at pump outlet.

Remove cap from quick dis-

connect coupling (1).

Connect pressure gage to

quick disconnect coupling.

Ensure that pressure gage

hose is long enough to read

gage from operator’s seat.

If necessary, warm hydraulic oi1 to operating temperature:

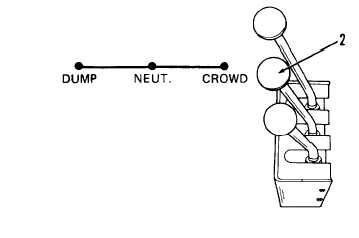

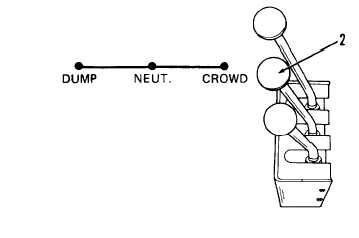

(a) Start and operate engine at full throttle.

(b) Place BUCKET control lever (2) in CROWD position and

hold for 15 seconds.

3-615