TM 5-3805-262-34

4-1. ENGINE MAINTENANCE (CONT)

d. Crankshaft and Main Bearings (Cont).

INSPECTION/REPAIR (SHEET 2 OF 3)

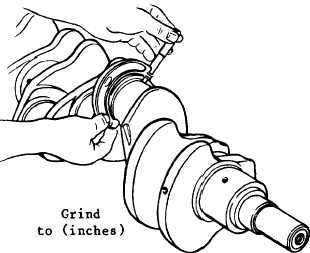

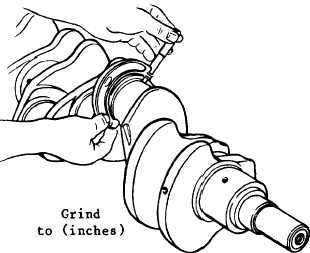

(5)

Check connecting rod journals for

wear using micrometer. If diame-

ters are smaller than 2.748

inches use undersize (0.002 inch)

inserts. If connecting rod jour-

nals are worn more than 0.002

inch, grind undersize to follow-

ing dimensions:

Outer Diameter

Undersize (inch)

0.010

0.020

0.030

NOTE

If one or more journals are to be

2.738 to 2.739

2.728 to 2.729

2.718 to 2.719

ground, grind all journals.

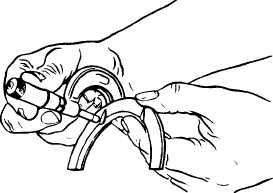

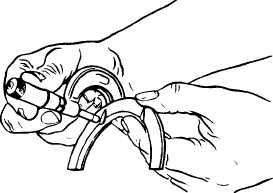

(6) Measure front and rear of each journal using micrometer, checking taper.

If taper exceeds 0.0005 inch, connecting rod journals must be ground.

Check connecting rod journals 90 degrees from first measurements for

out-of-roundness. If out-of-roundness exceeds 0.0005 inch, connecting rod

journals must be ground.

NOTE

If crankshaft journals are reground, repeat steps (3) through (6) above.

(7) Using micrometer, measure thickness

of thrust washers (15). Replace

thrust washer if thickness is less

than 0.147 inch.

(8)

Inspect crankshaft gear (19) for

cracks, missing or broken teeth,

scoring, pits, or excessive wear.

(9)

Inspect main bearing liners (16 and

17) for cracks, scoring, pitting,

flaking, or signs of overheating.

Check liner back for bright spots.

(10) Check main bearing caps (12 thru 14) bore diameter as follows:

4-24