TM 5-3805-262-34

INSPECTION/REPAIR (SHEET 1 OF 3)

NOTE

Replace an item if inspection

indicates need for replacement.

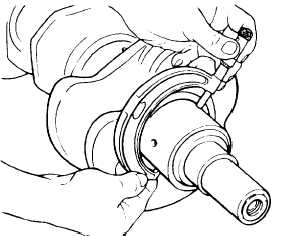

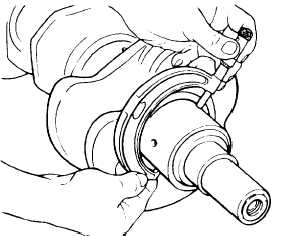

(1)

Inspect key (20) for cracks,

damage, or wear.

(2)

Inspect crankshaft (18) surfaces

for roughness, grooves, scores,

pits, cracks, or evidence of

overheating.

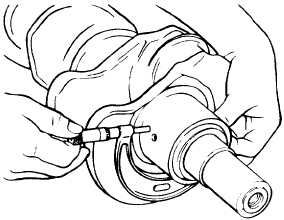

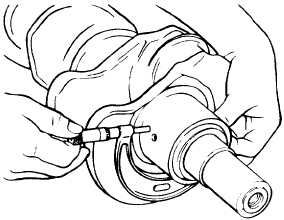

(3)

Measure crankshaft (18) main

bearing journals using micrometer

at front and rear of each jour-

nal. If diameters are smaller

than 2.998 inches, use undersize

(0.002 inch) bearing liners. If

main bearing journals are worn

more than 0.002 inch, grind un-

dersize to following dimensions:

Outer Diameter

Undersize (inch)

0.010

0.020

0.030

NOTE

(4)

Grind

to (inches)

2.988 to 2.989

2.978 to 2.979

2.968 to 2.969

If one or more journals are to be ground, grind all journals.

Check main bearing journals 90

degrees from first measurements

for out-of-roundness. If out-

of-roundness exceeds 0.005

inch, regrind journals and use

undersize liners.

4-23