TM 5-3805-290-23-2

ELECTRICAL GENERAL MAINTENANCE INSTRUCTIONS - CONTINUED

0022 00

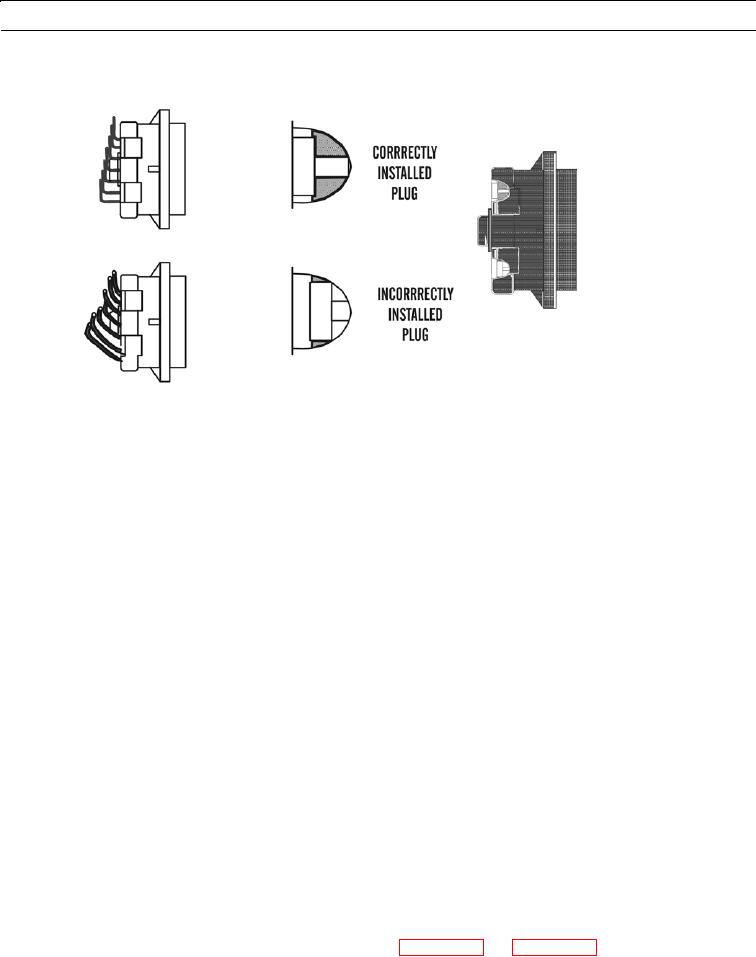

ELECTRICAL CONNECTORS INSPECTION - CONTINUED

0022 00

427-B2074

N OT E

Perform this procedure to determine if connector is cause of problem. If problem is found in electrical connec-

tor, repair connector and verify that problem has been corrected.

Many operational procedures and diagnostic code procedures in this work package will advise to check spe-

cific electrical connector. Engine uses variety of Deutsch and AMP connectors.

Intermittent electrical problems are often caused by poor connections. Always check for active diagnostic code

before breaking any connections. Also, always check for active diagnostic code after connector is connected to

verify problem is eliminated. Do not use dielectric grease on connectors.

Simply disconnecting and connecting connectors can temporarily solve problem at times. If this occurs, check

for these conditions:

a.

Loose terminals

b.

Bent terminals

c.

Improperly crimped terminals

d.

Corrosion

e.

Improper harness routing

Original source of problem must then be identified to ensure problem does not recur.

1.

Check locking of DT connector (Deutsch) and check lock ring of HD style connector (Deutsch).

a.

Ensure connector is properly locked. Also ensure two halves of connector cannot be pulled apart.

b.

Verify connector latch tab is properly latched. Also verify connector latch tab returns to fully latched position.

c.

Expected Results. Connector will securely lock. Connector and locking mechanism is without cracks or breaks.

(1)

If results are OK, proceed to step 2.

(2)

If results are NOT OK, repair or replace connectors. Ensure all seals are properly in place and that connec-

tors are completely connected. Verify repair eliminates the problem.

(3)

If results are NOT OK, replace wiring harness (WP 0169 00 thru WP 0175 00). Ensure all seals are prop-

erly in place and that connectors are completely connected. Verify repair eliminated the problem.

0022 00-16