TM 5-3805-290-23-2

ELECTRICAL GENERAL MAINTENANCE INSTRUCTIONS - CONTINUED

0022 00

ELECTRICAL CONNECTORS INSPECTION - CONTINUED

N OT E

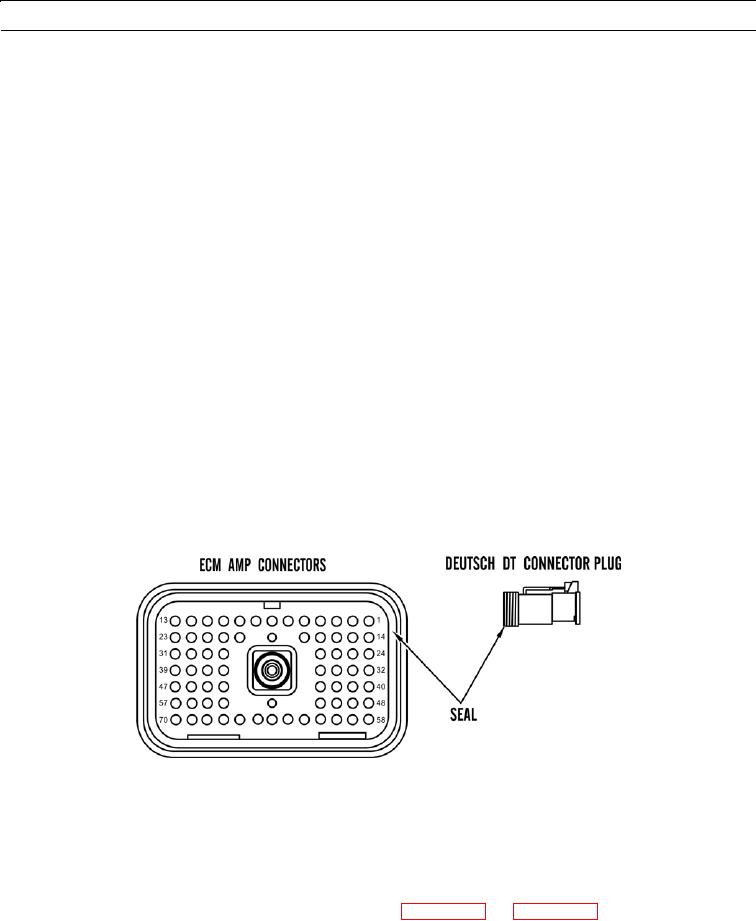

It is normal to see some minor seal abrasion on ECM connector seals. Minor seal abrasion will not allow

entry of moisture.

d.

If moisture or corrosion is evident in connector, source of moisture entry must be found and repaired. If source of

moisture entry is not repaired, problem will reoccur. Drying connector will not fix problem. Likely paths for

entrance of moisture are:

(1)

Missing seals

(2)

Improperly installed seals

(3)

Nicks in exposed insulation

(4)

Improperly mated connectors

C AU T I O N

If corrosion is evident on pins, sockets, or connectors, use only denatured alcohol to remove corrosion. Use cot-

ton swab or soft brush to remove corrosion. Do not use any cleaners that contain 1,1,1 trichloro-ethylene

because 1,1,1 trichloro-ethylene may damage connector.

Moisture can also travel from one connector through inside of wire to ECM Connector. If moisture is found in

ECM connector, thoroughly check all connectors and wires on harness that connect to ECM. ECM is not

source of moisture. Do not replace ECM if moisture is found in either ECM connector.

427-B0701

e.

Expected Results. All connectors should be completely connected and all seals should be completely inserted. Har-

ness and wiring should be free of corrosion, abrasions, or pinch points.

(1)

If results are OK, proceed to step 4.

(2)

If results are NOT OK, repair or replace connectors. Ensure all seals are properly in place and that connec-

tors are completely connected. Verify repair eliminates the problem.

(3)

If results are NOT OK, replace wiring harness (WP 0169 00 thru WP 0175 00). Ensure all seals are prop-

erly in place and that connectors are completely connected. Verify repair eliminated the problem by run-

ning engine for several minutes and checking again for moisture. If repair has not eliminated fault, proceed

to step 7.

0022 00-19