TM 5-3805-290-23-2

TURBOCHARGER AND OIL LINES REPLACEMENT - CONTINUED

0165 00

INSPECTION

WARN I N G

Hot engine components can cause injury from burns. Before performing maintenance on the engine,

allow the engine and the components to cool.

N OT E

Before you begin inspecting turbocharger, run engine and be sure that inlet air restriction is within spec-

ifications. Be sure that exhaust system restriction is within specifications.

The condition of turbocharger will have definite effects on engine performance. Use following inspec-

tions and procedures to determine condition of turbocharger.

1.

Remove air cleaner from compressor inlet (WP 0032

2.

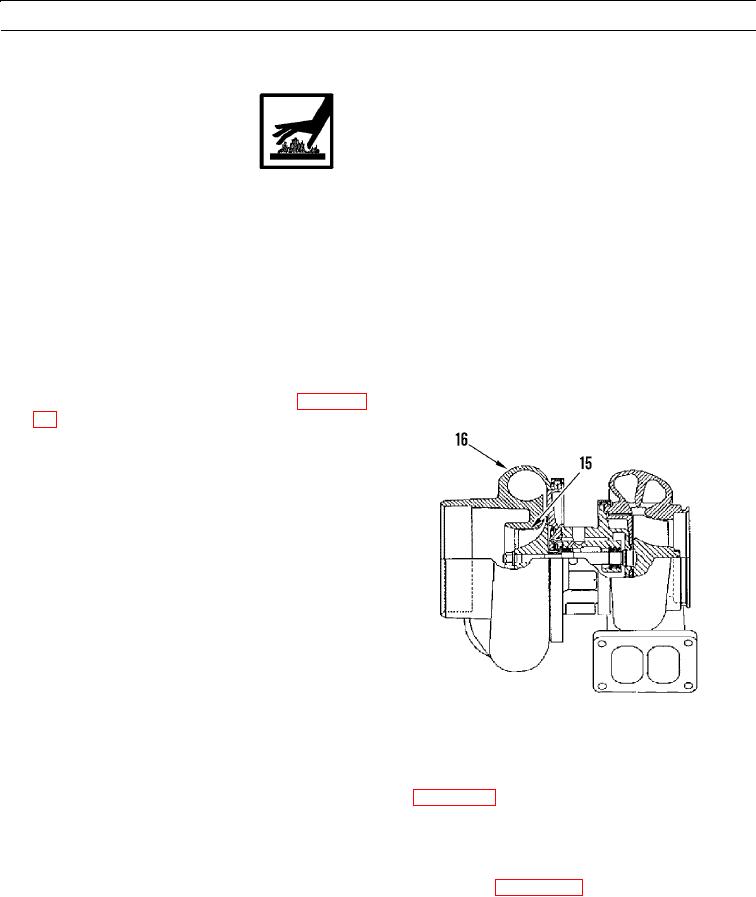

Inspect compressor wheel (15) for damage from for-

eign objects. If there is damage, determine source of

foreign object. As required, clean and repair inlet sys-

tem. Replace turbocharger if damaged.

3.

Clean compressor wheel (15) and compressor housing

(16) if you find buildup of foreign material.

4.

Turn rotating assembly by hand. While turning, push

assembly sideways. Assembly should turn freely.

Compressor wheel (15) should not rub compressor

housing (16). Turbocharger must be replaced if com-

pressor wheel rubs compressor housing.

427-B0124-1

5.

Inspect compressor wheel (15) and compressor housing (16) for oil leakage. An oil leak from compressor may deposit

oil in aftercooler. If oil is found in aftercooler, drain and clean (WP 0034 00).

a.

Check oil level in crankcase. If oil level is too high, adjust oil level.

b.

Inspect air cleaner element for restriction. If restriction is found, correct problem.

c.

Inspect engine crankcase breather. Clean or replace breather if plugged (WP 0024 00).

d.

Remove oil drain tube. Inspect oil drain hole and oil drain tube for oil sludge. Inspect area between bearings of

rotating assembly shaft. If necessary, clean rotating assembly shaft, oil drain hole, and oil drain tube.

e.

If steps 5a thru 5d did not reveal source of oil leakage, turbocharger has internal damage. Replace turbocharger.

0165 00-5