TM 5-3805-291-23-1

THEORY OF OPERATION - CONTINUED

0003 00

OIL COOLERS AND COOLING SYSTEM OPERATION - CONTINUED

427-C1748

a.

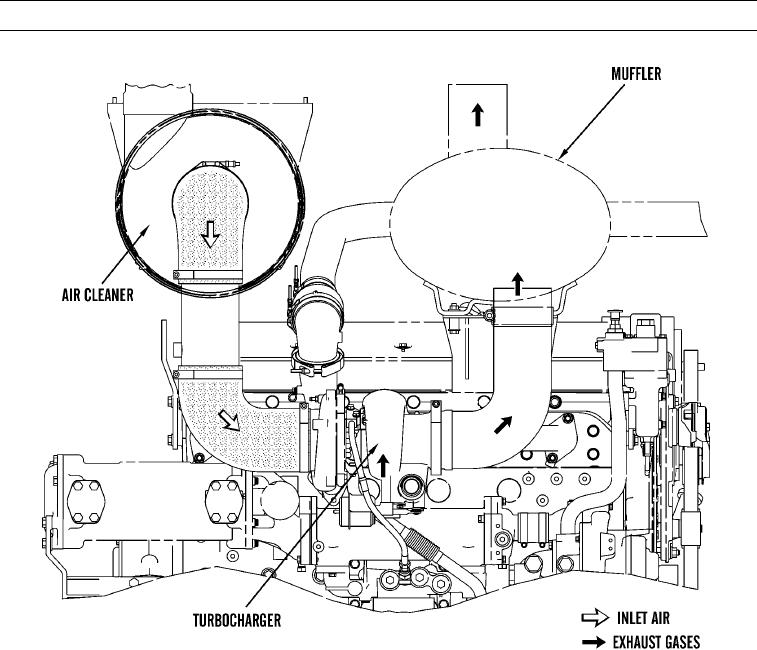

Air-to-air aftercooler system (ATAAC system) provides cooled air to air intake manifold on right side of machine.

Air is drawn in through air cleaner and into turbocharger. Turbocharger increases air pressure and temperature. Air

is sent through tube into aftercooler core. From core, air flows into air intake manifold. The aftercooler cools pres-

surized air from turbocharger to increase air density and provide more oxygen for combustion.

b.

Airflow from inlet port into cylinders is controlled by inlet valves. Each cylinder has inlet and exhaust valves in

cylinder head. Inlet valves open when piston moves downward on inlet stroke. When inlet valves open, cooled

compressed air from intake manifold is pulled into cylinder. Inlet valves close when piston begins to move upon

compression stroke.

c.

Air in cylinder is compressed and fuel is injected into cylinder when piston is near top of compression stroke.

Combustion begins when fuel mixes with air. Force of combustion pushes piston downward on power stroke.

Exhaust valves open and exhaust gases are pushed through exhaust port.

d.

Exhaust gases from exhaust manifold flow into turbine side of turbocharger. High pressure exhaust gases cause

turbocharger turbine wheel to rotate. Turbine wheel is connected to shaft that drives compressor wheel. Exhaust

gases from turbocharger pass through exhaust outlet, through a muffler, and through exhaust stack.

e.

Engine efficiency will increase due to cooler inlet air. This helps to provide lowered fuel consumption and

increased horsepower output.

0003 00-65