TM 5-3805-291-23-1

THEORY OF OPERATION - CONTINUED

0003 00

OIL COOLERS AND COOLING SYSTEM OPERATION - CONTINUED

427-C1746

4.

Axle Oil Cooler.

a.

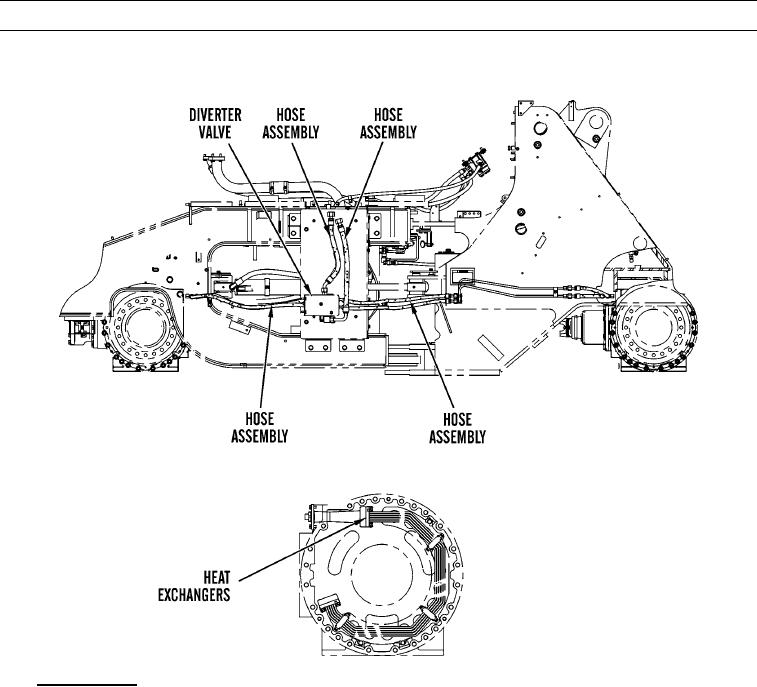

Axle oil cooler system consists of diverter valve, two heat exchangers, and four hose assemblies.

b.

Rear axle has a temperature set switch which monitors axle oil temperature. Contacts for temperature switch close

when axle oil reaches switch actuation temperature of 257 5F (125 3C). When temperature switch contacts

close, an alert indicator in cab will activate.

c.

Hydraulic oil cooler core is mounted on back of radiator group and continuously supplies cool hydraulic oil to axle

oil cooler system. Hydraulic oil flows through upper left hose assembly to diverter valve. At diverter valve,

hydraulic oil flows to front and rear axles through two lower hose assemblies.

d.

At each axle, hydraulic oil flows through heat exchangers. Heat from axle oil is transferred to hydraulic oil in heat

exchangers. Hydraulic oil then flows through two lower hose assemblies to diverter valve. This oil flows through

upper right hose assembly to hydraulic tank.

e.

Two bypass check valves for axle oil cooler system are located in diverter valve. Bypass check valves limit oil

pressure in heat exchangers. Bypass check valves are rated at 25 psi (172 kPa) at 0.25 US gpm (0.95 L/min). If

bypass check valves open, hydraulic oil bypasses heat exchangers.

0003 00-66