TM 5-3805-291-23-1

THEORY OF OPERATION - CONTINUED

0003 00

ELECTRO-HYDRAULIC SYSTEM - CONTINUED

427-C1819

(2)

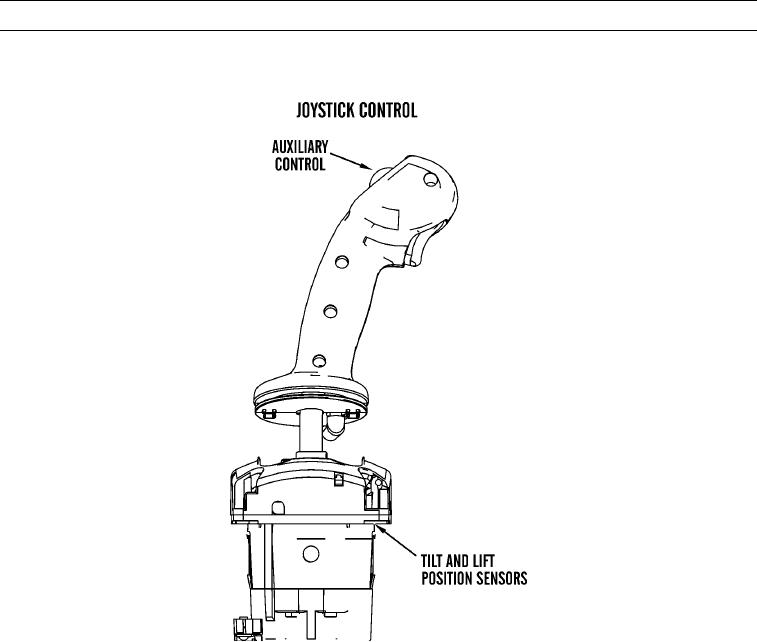

Position sensors for lift and tilt features are PWM sensors. This sensor signal's frequency is constant at

approximately 500 Hz. Machine electrical system provides +battery voltage to joystick control sensors for

operating power. Power is supplied to thumbwheel by 8V ECM sensor supply.

(3)

Soft Detents. Soft detents in joystick control are mechanical, but detents do not latch. Joystick control

detents are controlled by software within implement ECM. As joystick control is moved into detent posi-

tion, linkage will travel to a preprogrammed kickout position. Joystick should be released to HOLD posi-

tion. Linkage movement will continue until kickout is reached. Any 6 degree movement of joystick control

from HOLD position will override detents. Kickouts will not be activated if joystick control is held in

detent position for more than one second. If control is not returned to HOLD position within 0.75 seconds,

kickout will not continue.

0003 00-151