TM 5-3805-291-23-1

TROUBLESHOOTING WITHOUT A DIAGNOSTIC CODE - CONTINUED

0008 00

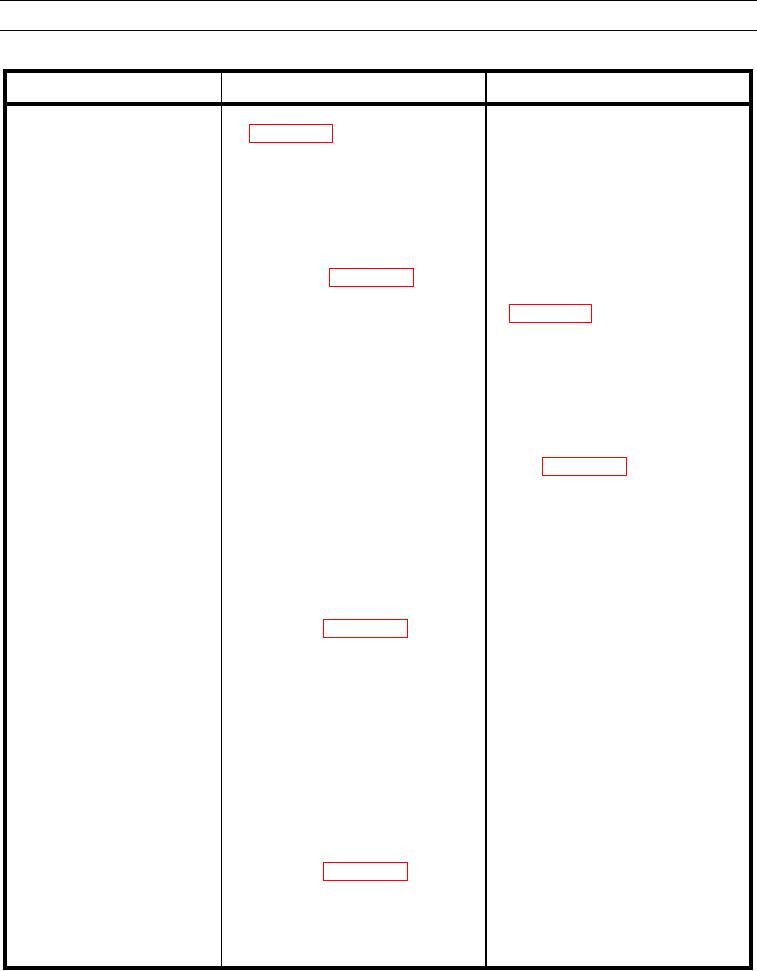

Table 1. Engine Troubleshooting - Continued.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

Engine Cranks but Will Not 6. Perform Fuel System Pressure Test

If problem still exists, go to Test 7.

2.

Start - Continued.

7. Check for air in the low pressure supply 1. Prime fuel system (TM 5-3805-291-

system if any of the following

10).

procedures have been performed:

2. If problem still exists, go to Test 8.

replacement of the fuel filters, service

on the low pressure fuel supply circuit,

or replacement of the fuel injectors.

8. Connect MSD (WP 0005 00) and check 1. Troubleshoot any active codes before

for active diagnostic codes.

continuing with the procedure. Refer to

2. If problem still exists, go to Test 9.

9. Crank the engine and observe the

1. If engine speed is present, confirm

engine speed on the ET status screen.

crankshaft and camshaft speed timing

(Initial cranking may indicate engine

sensor are flush against the housing

speed is abnormal. Message will be

(WP 0076 00 and WP 0078 00).

replaced when ECM calculates speed

2. If engine speed is not present, perform

Engine Speed Timing Sensor Circuit

from signal).

Test (WP 0013 00).

3. If problem still exists, go to Test 10.

10. If an erratic noise occurs during

1. If damaged, replace starter motor (WP

cranking, remove starter motor (WP

0051 00) or flywheel (WP 0177 00).

0051 00) and check starter motor

2. If problem still exists, go to Test 11.

pinion and flywheel ring gear for

damage (WP 0177 00).

11. Perform Electrical Power Supply

If problem still exists, go to Test 12.

Circuit Test (WP 0013 00).

12. If cold conditions exist, check

1. If starting aid is inoperative, perform

Ether Injection System Test (WP 0013

operation of starting aid (TM 5-3805-

291-10).

00).

2. If problem still exists, go to Test 13.

13. Ensure injector wiring harness is fully

1. Verify harness connection is not faulty.

connected and free of corrosion (WP

Replace, if necessary (WP 0187 00).

0187 00).

2. If problem still exists, go to Test 14.

14. Use MSD to perform Injector Solenoid If problem still exists, go to Test 15.

Test to confirm that all injector

solenoids are being energized by the

ECM. If not, perform Injector solenoid

Circuit Test (WP 0013 00).

15. Remove valve cover and look for

1. Repair any damage.

obvious signs of mechanical problems. 2. If problem still exists, go to Test 16.

0008 00-3