TM 5-3805-291-23-1

TROUBLESHOOTING WITHOUT A DIAGNOSTIC CODE - CONTINUED

0008 00

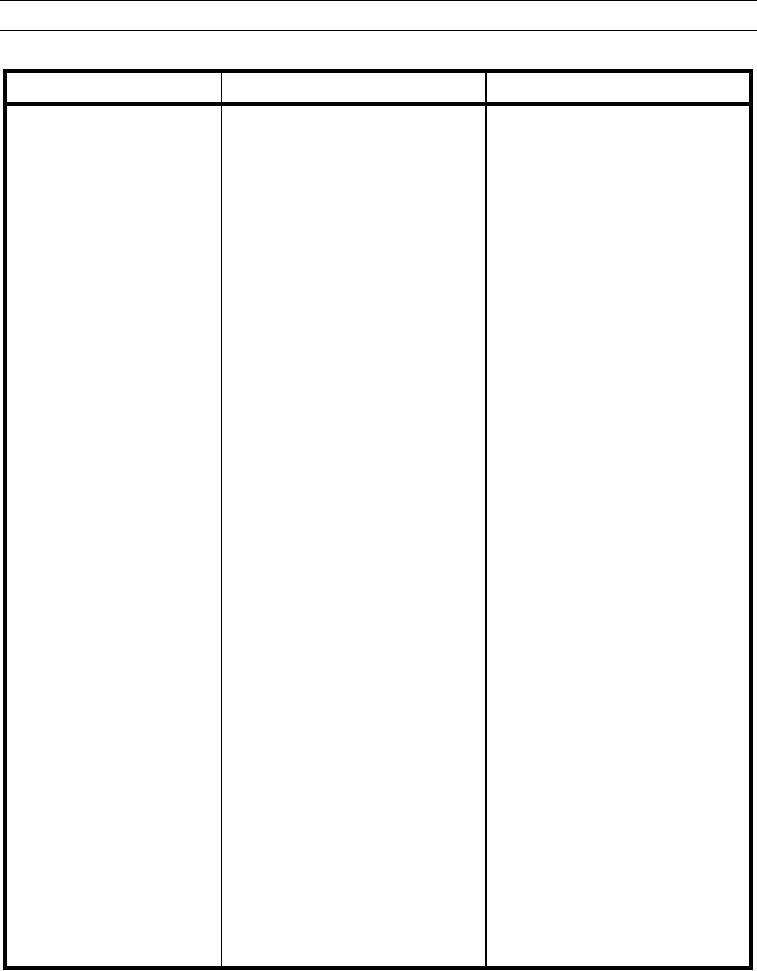

Table 2. Electrical System Troubleshooting - Continued.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

Backup Alarm Always On - 2. Check if problem is still active.

1. If problem still exists, replace backup

5.

(a) Inspect and clean harness

alarm relay (WP 0053 00).

Continued.

connector contacts.

2. If problem still exists, replace

(b) Reconnect all harness connectors.

powertrain ECM (WP 0063 00).

(c) Start engine (TM 5-3805-291-10). 3. If problem is no longer active, initial

problem was probably caused by a poor

electrical connection and/or a short in

a harness connector that was

disconnected and reconnected.

Resume normal machine operation.

1. Determine condition.

1. If one worklight is inoperative, replace

6.

One or More Worklights

worklight bulb (WP 0072 00). If

Are Inoperative.

problem still exists, go to Test 2.

2. If both front or both rear worklights are

inoperative, check and replace

worklight fuse(s) as necessary (TM 5-

3805-291-10). If problem still exists,

go to Test 4.

3. If all worklights are inoperative, go to

Test 10.

2. Check for open power circuit.

1. If battery voltage is present, go to Test

(a) Disconnect wiring harness from

3.

worklight housing (WP 0072 00). 2. If battery voltage is not present, there

(b) Turn battery disconnect, engine

is an open circuit between worklight

start, and worklight switches to

switch and worklight housing. Replace

ON position (TM 5-3805-291-10).

wiring harness in question (WP 0195

(c) Select service drive mode on main

00 thru WP 0201 00).

light switch (TM 5-3805-291-10).

(d) If rear worklight is inoperative,

measure voltage at worklight

between wiring harness pin 1, wire

619 (GN), and ground.

(e) If front worklight is inoperative,

measure voltage at worklight

between wiring harness pin 1, wire

607 (PK), and ground.