TM 5-3805-291-23-1

BRAKE SYSTEM TESTS, INSPECTIONS, AND ADJUSTMENTS - CONTINUED

0015 00

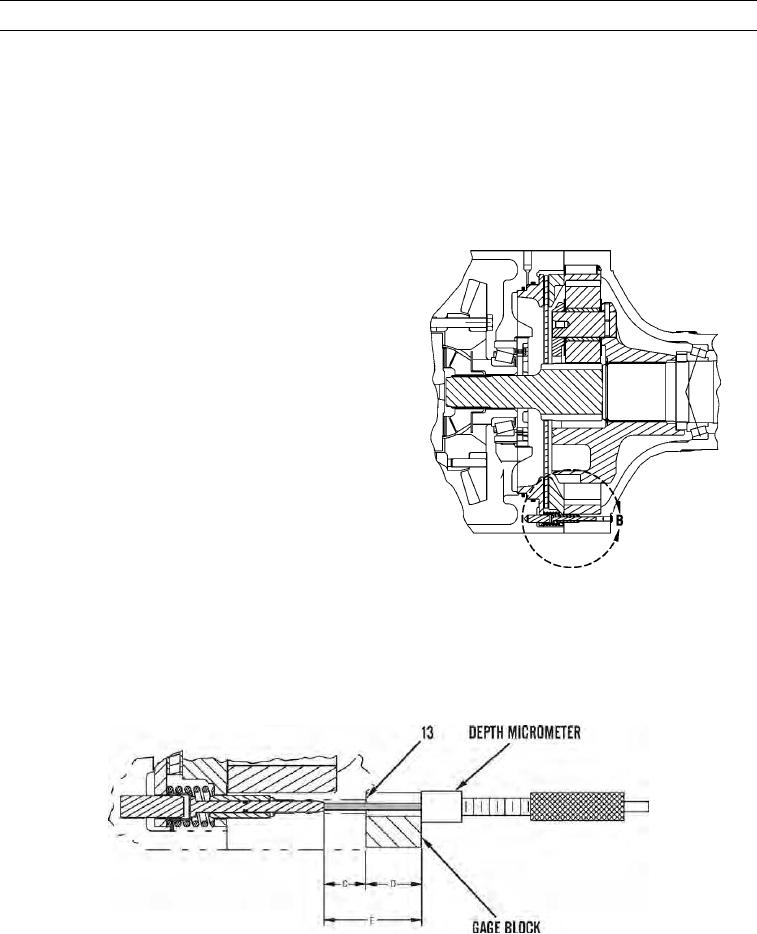

SERVICE BRAKE WEAR INDICATOR (NEW BRAKE DISC) CHECK - CONTINUED

N OT E

Measure dimension (C) with the service brakes APPLIED. Dimension (C) equals distance from axle hous-

ing flange face to end of pin.

7.

Use caliper to measure exact thickness (D) of gage block.

8.

Gage block is U shaped. Position gage block so slot straddles hole in axle housing flange face (13). Firmly hold gage

block against axle housing flange face.

9.

With assistance, apply service brakes (TM 5-3805-

291-10).

10.

Using depth micrometer, measure dimension (E).

N OT E

If gage block is not available, use a

depth micrometer with a half of a base.

Shorten the base on the micrometer by

grinding. This will help allow the base of

the micrometer to rest on flange face.

Measure dimension directly from flange

face.

427-C2018

11.

Value of dimension (C) equals value of dimension (E) minus value of dimension (D).

12.

Record measurements for each brake that contains a new brake disc.

13.

Record number of service hours shown on service meter unit (SMU).

427-C0871

DETAIL B

0015 00-10