TM 5-3805-291-23-1

ELECTRICAL GENERAL MAINTENANCE INSTRUCTIONS - CONTINUED

0022 00

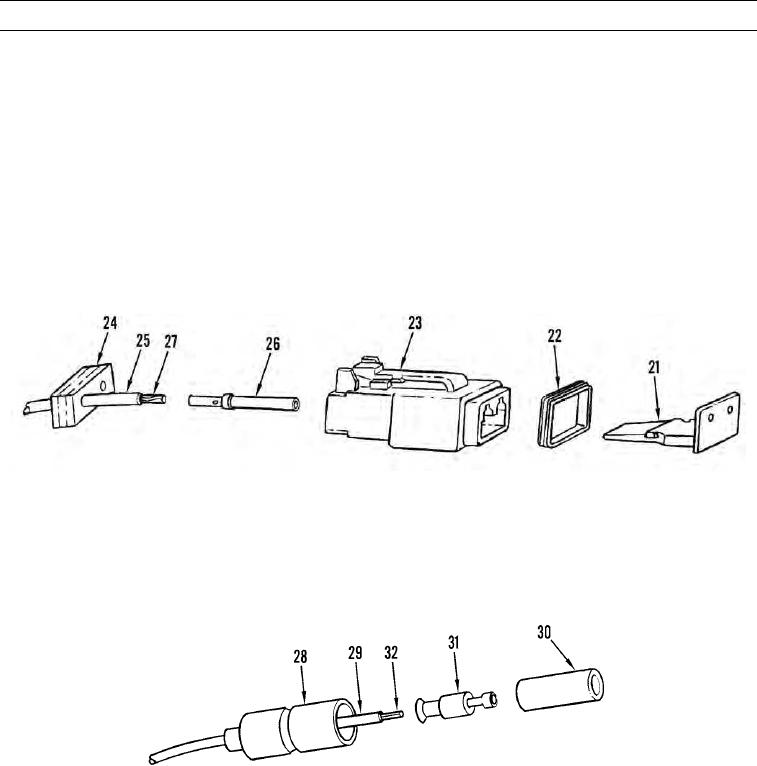

WATERPROOF CONNECTOR REPAIR - CONTINUED

N OT E

Perform steps 6 thru 9 only if pin was removed.

6.

Using wire stripping tool, strip insulation from wire (25) to expose 1/4 in. (6 mm) length of metal strands (27).

7.

Insert metal strands (27) of wire (25) fully into rear of pin (26).

8.

Using crimping tool, securely crimp pin (26) to metal strands (27) of wire (25).

9.

Push pin (26) into rear of connector (23) until fully seated.

10.

Install seal (24) on rear of connector (23).

11.

Install gasket (22) and end cover (21) on front of connector (23).

427-C1863

0022 00

MILITARY CONNECTOR REPAIR

1.

Slide shell (28) back on wire (29) to expose sleeve (30).

2.

Remove sleeve (30) from terminal (31) by pulling sleeve forward.

3.

If defective, remove terminal (31) from wire (29) by cutting through wire just behind terminal.

427-C1864

N OT E

Perform steps 4 thru 6 only if terminal was removed.

4.

Using wire stripping tool, strip insulation from wire (29) to expose length of metal strands (32) equal to depth of termi-

nal (31).

5.

Using crimping tool, securely crimp terminal (31) to metal strands (32) of wire (29).

6.

Install sleeve (30) on terminal (31) by pushing sleeve over front of terminal until fully seated.

7.

Slide shell (28) up wire (29) and over sleeve (30).

0022 00-6