TM 5-3805-291-23-2

PARKING BRAKE ACTUATOR REPLACEMENT - CONTINUED

0112 00

ADJUSTMENT - CONTINUED

Adjustment Procedure

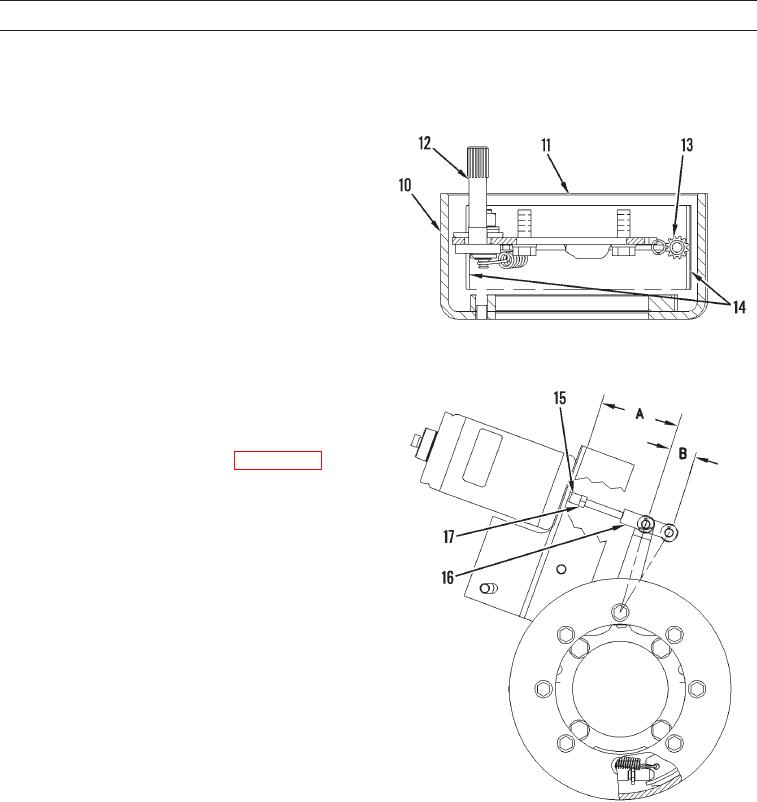

1.

Place brake drum (10) on a flat surface. Make sure that

large diameter of brake drum is facing upward. Place

brake group (11) into brake drum. Make sure that

camshaft (12) is facing upward.

2.

Rotate starwheel (13) in order to move brake

shoes (14) outward. Rotate starwheel until brake shoes

contact brake drum (10). Make sure that brake shoes

stay above radius at the bottom of brake drum.

3.

Rotate starwheel (13) so that brake shoes (14) press

against brake drum (10). The force of brake shoes

against brake drum should be sufficient to hold brake

shoes to brake drum when you lift brake group (11)

upward.

427-C1994

4.

Lift brake group (11) upward. Place brake drum (10)

and brake group on the flat surface.

5.

Rotate starwheel (13) for 15 clicks in order to release

the pressure of brake shoes (14) on brake drum (10).

6.

Install parking brake on machine (WP 0113 00).

7.

Apply the parking brake. Actuator shaft (15) should be

retracted.

8.

Adjust rod end (16) by turning the actuator shaft (15)

in order to achieve dimension (A) of 4.134 in.

(105 mm).

9.

Release parking brake in order to extend the actuator

shaft (15).

427-C1995

0112 00-4