TM 5-3805-291-23-2

DIFFERENTIAL AND FINAL DRIVE OIL CHANGE - CONTINUED

0111 00

DIFFERENTIAL AND FINAL DRIVE OIL CHANGE

C AU T I O N

Wipe area clean around all connections to be opened during removal. Cap lines and hoses and plug

openings after removing lines. Contamination of system could result in premature failure.

N OT E

Use a container to catch any fluid that may drainfrom hoses or system. Dispose of fluid IAW local

policy and ordinances. Ensure all spills are cleaned up.

The axle housings are equipped with ecology drain valves.

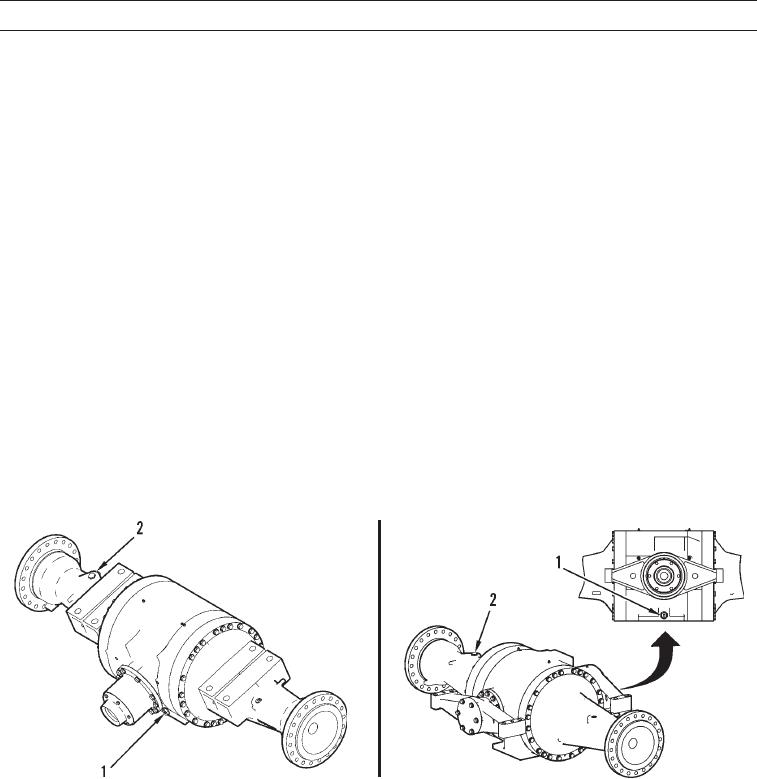

1.

Remove one drain plug (1) from each axle. Attach hose to drain adapter and install adapter in drain valve. Allow oil to

drain into container.

2.

Clean and install drain plug (1) for each axle.

3.

Clean area around dipstick/fill plugs (2) on each axle.

4.

Remove the dipstick/fill plugs (2) from each axle.

N OT E

Axle capacity is 16.9 gal. (64 L), which includes 0.3 gal. (1 L) of axle oil additive.

5.

Add 1.06 qt (1.0 L) of axle oil additive to each axle.

6.

Fill each axle with oil.

7.

Clean and install level gage/fill plugs (2) on each axle.

427-C0340

427-C0341

8.

Start machine (TM 5-3805-291-10).

9.

Operate machine and drive for a few minutes (TM 5-3805-291-10).

10.

Shut off machine (TM 5-3805-291-10).

11.

Let oil settle for a few minutes.

12.

Check oil level in axle.

13.

Check for leaks.

END OF WORK PACKAGE

0111 00-2