TM 5-3805-291-23-2

BUCKET TIPS AND CUTTING EDGES REPLACEMENT - CONTINUED

0170 00

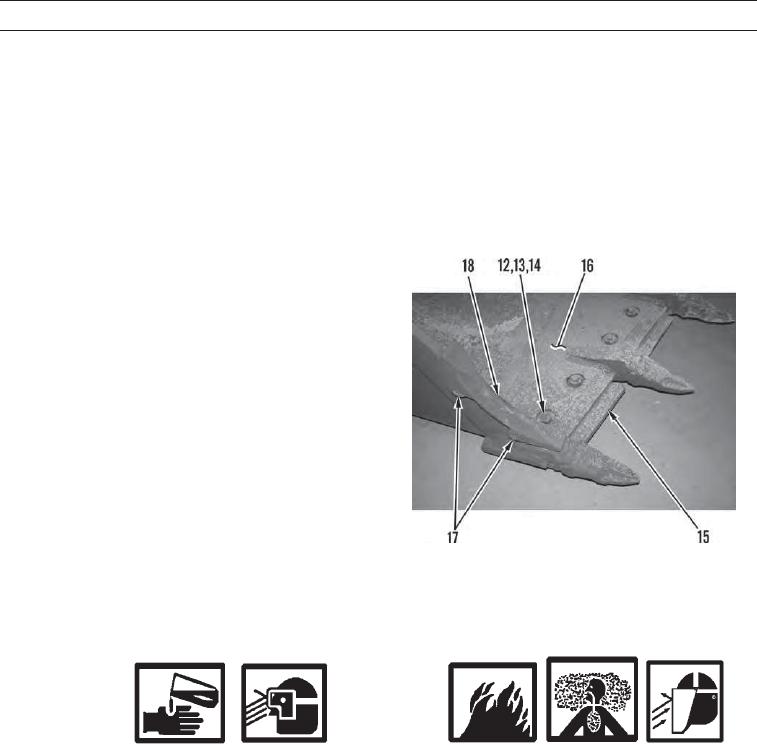

BUCKET CUTTING EDGES INSPECTION/REMOVAL

N OT E

Check cutting edges and end bits for wear or damage. Use this procedure to service cutting edges and

end bits.

If opposite side of cutting edge is not worn, it may be used. End bits are not reversible.

If both sides of cutting edge are worn, install new cutting edge.

Number of fasteners used on cutting edges is dependent upon the type of bucket (GP or rock).

1.

Start machine (TM 5-3805-291-10).

2.

Raise bucket and place blocking under bucket. Lower

bucket onto blocking (TM 5-3805-291-10).

3.

Stop engine (TM 5-3805-291-10).

4.

Remove bolts (12), nuts (13), washers (14), and cut-

ting edges (15) from bucket (16).

5.

Use hammer and punch or pin-master tool to remove

two pins (17) and corner edge (18) from bucket (16).

6.

Repeat step 5 for opposite side of bucket (16).

427-C1219

BUCKET CUTTING EDGES CLEANING

WARN I N G

Solvent cleaning compound MIL-PRF-680 Type III is an environmentally compliant and low-toxic

material. However, it may be irritating to the eyes and skin. Use protective gloves and goggles. Use in

well-ventilated areas. Keep away from open flames and other sources of ignition. Failure to do so may

result in injury or death to personnel.

Particles blown by compressed air are hazardous. DO NOT exceed 15 psi (103 kPa) nozzle pressure

when drying parts with compressed air. DO NOT direct compressed air against human skin. Make

sure air stream is directed away from user and other personnel in the area. To prevent injury, user

must wear protective goggles or face shield. Failure to follow this warning may result in injury to per-

sonnel.

1.

Clean all parts and surfaces with solvent cleaning compound.

2.

Dry parts with compressed air.

0170 00-6