TM 5-3805-292-10

0020

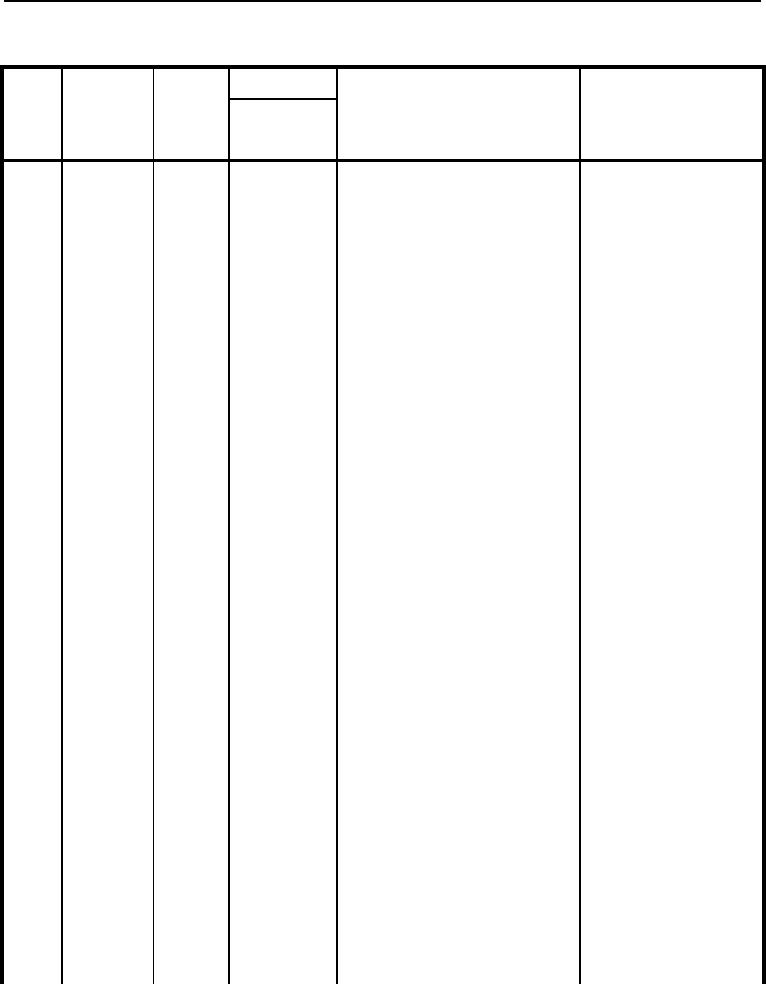

Table 1. Preventive Maintenance Checks and Services (PMCS)

for the M400T and M400W SSL - Continued.

LOCATION

ITEM TO

CHECK/

ITEM

MAN-

NOT READY/

SERVICE

NO.

INTERVAL

HOURS

PROCEDURE

AVAILABLE IF:

31

During

Horn and

a. If tactical situation permits,

Horn does not operate.

Backup Alarm

check operation of horn.

b. Move LH (ground drive) control Backup alarm does not

sound. Machine does not

lever slightly backward and

listen for backup alarm to sound. move in reverse.

Ensure machine moves in

reverse.

32

During

Control Levers a. Operate LH (ground drive)

Machine does not move

IAW LH (ground drive)

control lever through all

positions and ensure machine control lever position.

moves correctly in all directions.

Ensure machine stops when LH

(ground drive) control lever is

returned to neutral position.

b. Operate RH (loader) control

Lift and tilt cylinders do not

lever through all positions and operate IAW RH (loader)

control lever position.

ensure lift and tilt cylinders

operate correctly. Ensure lift and

tilt cylinder movement stops

when RH (loader) control lever

is returned to neutral position.

33

During

Boom Override Raise loader arm approximately

Loader arm does not

one foot and pull boom override

come down.

Valve

valve fully up. Loader arm should

come down.

34

During

Auxiliary

Press auxiliary hydraulic lockout

Loader arm or attachment

button on DIP and operate RH

coupler move.

Hydraulic

Lockout Button control lever. Loader arm and

attachment coupler should not

move.

35

During

Overall

a. Be alert for evidence of fluid

Class III oil or coolant

leaks are evident. Any fuel

Machine

leaks such as oil, coolant, or

leakage is evident.

fuel.

b. Be alert for proper operation of

Powertrain components

malfunction.

powertrain components.

c. Monitor operation of lift and tilt

Class III oil leaks are

evident.

cylinders. Be alert for oil leaks.

d. Monitor operation of work tool

Work tool does not

function properly.

attachment.

0020-32