TM 5-3805-292-10

0020

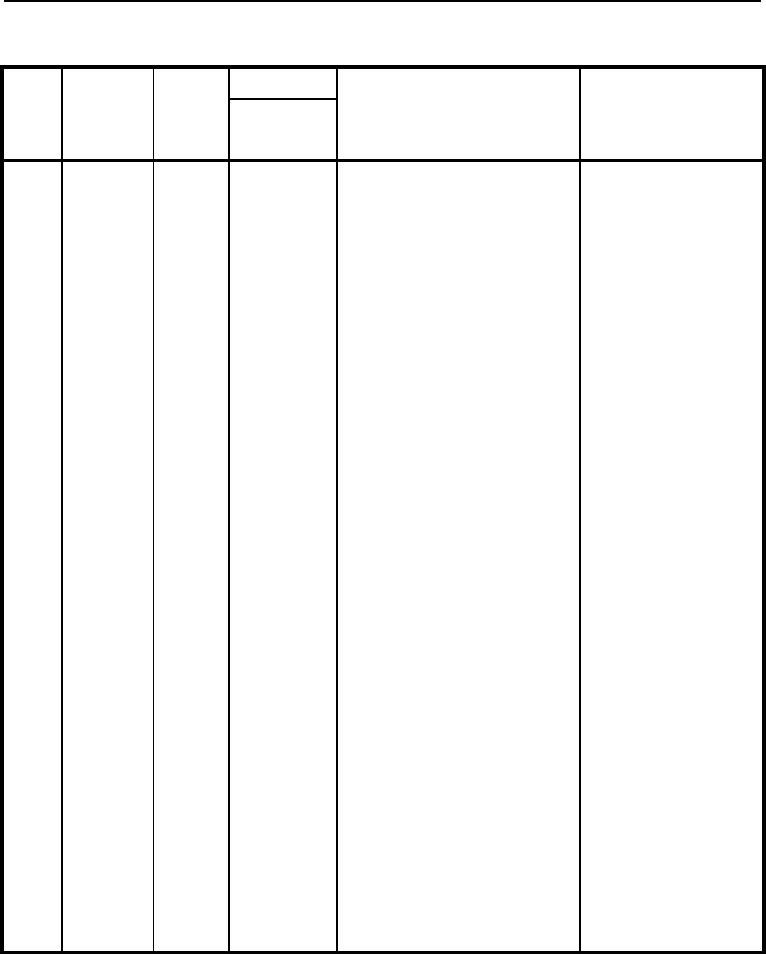

Table 2. Preventive Maintenance Checks and Services (PMCS)

for the Work Tool Attachments - Continued.

LOCATION

ITEM TO

CHECK/

ITEM

MAN-

NOT READY/

SERVICE

NO.

INTERVAL

HOURS

PROCEDURE

AVAILABLE IF:

7

After

Pallet Fork

a. Clean pallet fork.

b. Check for cracked, bent, or

Damage that would impair

operation is evident.

otherwise damaged fork frame

and fork tines. Inspect for

broken welds.

Fork tine locks do not

c. Ensure fork tine locks function

function.

and fork tines can be adjusted

side to side and locked into

position.

8

After

Auger

a. Clean auger.

b. Inspect for missing or broken

Teeth or point are missing

or broken.

teeth or point.

c. Inspect drive unit for cracks,

Cracks, damage, loose or

missing fasteners, or

damage, loose or missing

broken welds are evident.

fasteners, and broken welds.

d. Inspect pins/clevis pins for

Pins/clevis pins are

cracks, bends, breaks, or wear. cracked, bent, broken, or

worn.

e. Inspect drive unit output shaft

Output shaft is cracked,

bent, broken, or worn.

for cracks, bends, breaks, or

wear.

9

After

Hydraulic

a. Clean hydraulic hammer.

Hammer

b. Inspect hydraulic hammer kit for Cracks, damage, loose or

missing fasteners, or

cracks, damage, loose or

missing fasteners, and broken broken welds are evident.

welds.

c. Inspect hydraulic hose

Damage that would cause

Class III leaks is evident.

assemblies for cracks, brittle

covers, or other damage.

10

After

Container

Inspect for missing hardware and

Missing hardware,

cracked, bent, or otherwise

cracked, bent, or

damaged structure.

otherwise damaged

structure.

END OF WORK PACKAGE

0020-66