TM 5-3805-298-23-1

0035

Table 1. Engine Cranks But Does Not Run - Continued.

035

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

CAUTION

Engine Cranks But Does Not

Run - Continued

Fuel injection tubes must only be used once. Do not tighten fuel injection

tubes that have already been installed and tightened.

Failure to follow this caution may result in damage to equipment.

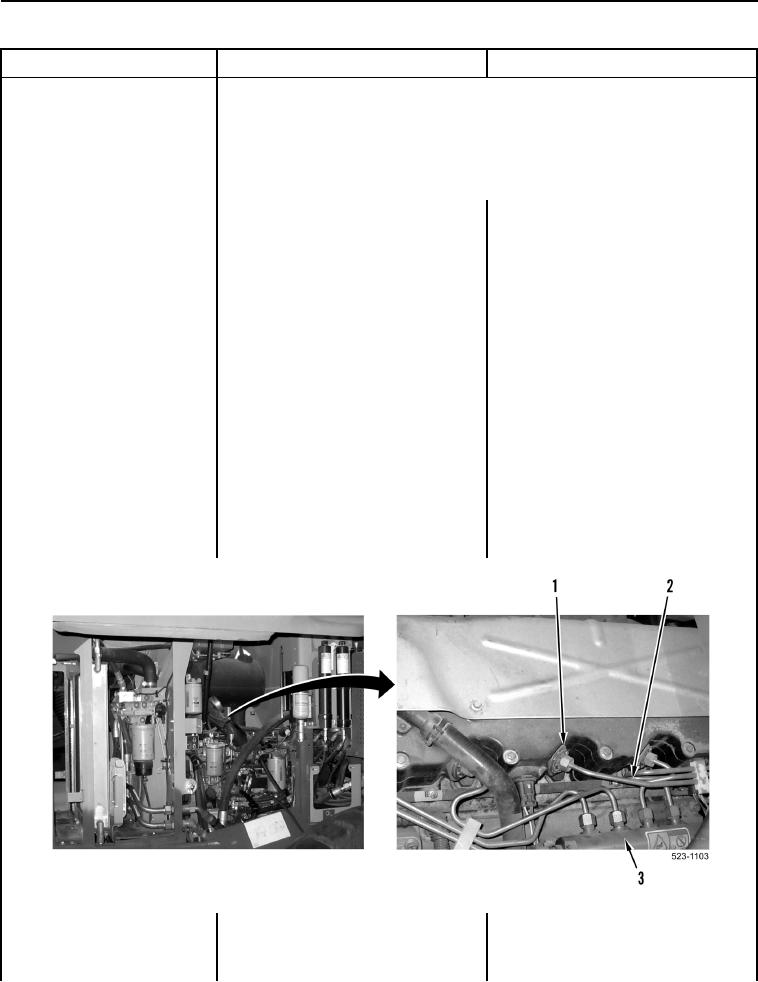

5. Inspect six fuel injection tubes

Fuel Injection Tubes OK - Proceed to

(Figure 16, Item 2) between fuel

step 6.

rail (Figure 16, Item 3) and six fuel

Fuel Injection Tube Leaks - Replace

injectors (Figure 16, Item 1) for

affected primary fuel injection tube

Class I, II, or III leaks.

(WP 0201).

Proceed to Test Step 12.

6. Inspect six fuel injection tubes

Fuel Injection Tubes OK - Release

(Figure 16, Item 2) between fuel

electric fuel priming pump switch

rail (Figure 16, Item 3) and six fuel

(TM 5-3805-298-10).

injectors (Figure 16, Item 1) for

Turn ignition switch and battery

sharp bends and pinched or

disconnect switch to the OFF position.

damaged areas.

Install air cleaner housing (WP 0204).

Proceed to Test Step 10.

Fuel Injection Tube Pinched,

Damaged, or Has Sharp Bends -

Replace fuel injection tube (WP 0201).

Proceed to Test Step 12.

Figure 16. Primary Fuel Injection Tube Between Fuel Rail and Fuel Injectors.

0035