TM 5-3805-298-23-2

0155

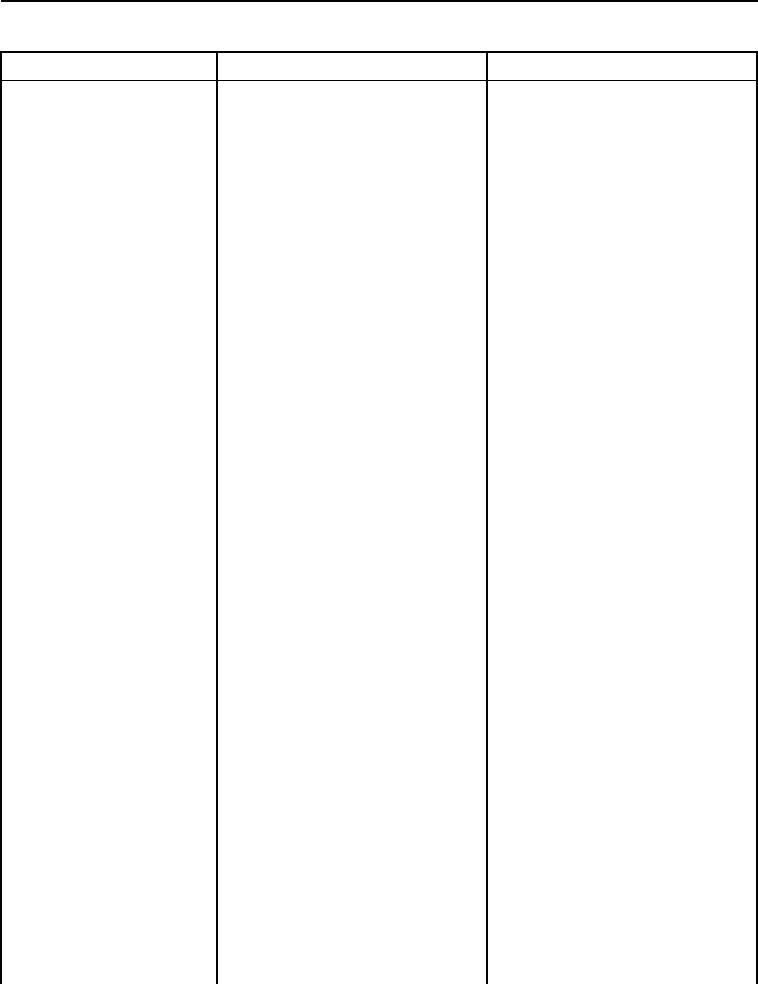

Table 1. Kickout System Will Not Operate or Operates Improperly Continued.

0155

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

Test Step 3. Test Kickout Sensors

Kickout System Will Not

Adjustment.

Operate or Operates

1. Set kickout switch to ON position

Improperly - Continued

(TM 5-3805-298-10).

2. Verify bucket/fork switch is set to

correct position for equipment

attached to machine

(TM 5-3805-298-10).

3. Adjust bucket, fork, lift, and carry

kickout position sensors

(WP 0297).

Test Step 4. Inspect Carry Kickout

Position Sensor Components.

1. Turn ignition switch and battery

disconnect switch to OFF position

(TM 5-3805-298-10).

2. Inspect carry kickout position

Kickout System Components OK

sensor (Figure 1, Item 6), wiring

Proceed to step 3.

harness (Figure 1, Item 5),

Kickout System Component(s)

mounting brackets (Figure 1,

Corroded or Damaged Replace

Items 3 and 4), bolts (Figure 1,

corroded or damaged kickout system

Item 1), and washers (Figure 1,

components as necessary (WP 0297).

Item 2) for corrosion and damage.

Proceed to Test Step 60.

0155-3