12

TM 5-2420-231-23-3

FIELD MAINTENANCE

-

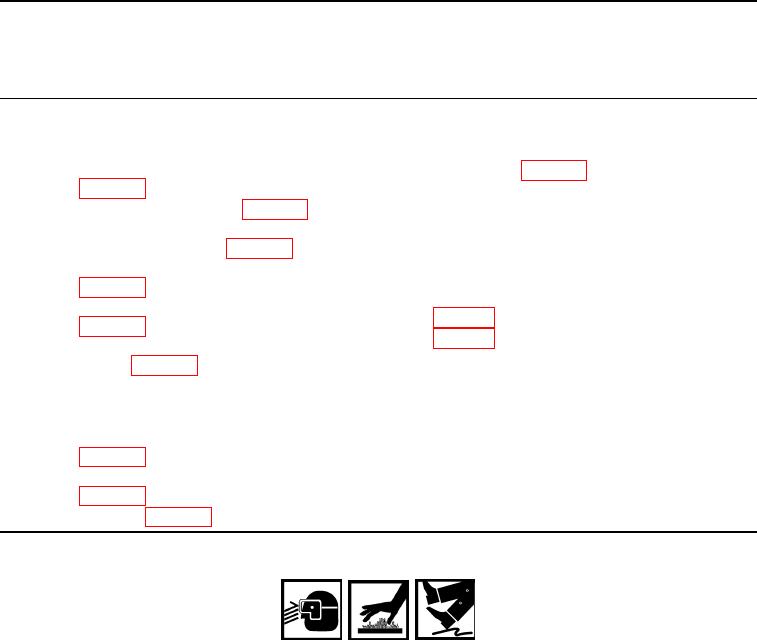

BACKHOE BUCKET CYLINDER REPLACEMENT

0

276

Removal, Cleaning and Inspection, Installation

INITIAL SETUP

Materials/Parts - Continued

Tools and Special Tools

Tool Kit, General Mechanic's

Tag, Marker (WP 0375, Item 33)

0

0

(WP 0376, Item 117)

Locknut (3)

0

Pan, Drain, 5 gal. Capacity (WP 0376, Item 54)

O-ring (2)

0

0

Pliers, Retaining Ring, Fixed Tip, Convertible,

0

Personnel Required

0/.090" Tips, 8-21/32" (WP 0376, Item 59)

Two

Sling, Eye (Nylon, 4 ft x 1 in.)

0

0

(WP 0376, Item 79)

References

Wrench, Combination, 12 Pt, 1-1/4"

0

0

(WP 0376, Item 125)

WP 0374 (Group Number 0713, 0717, and

0

Wrench, Combination, Standard Length, 12 Pt,

0

0743)

1-1/16" (WP 0376, Item 127)

Equipment Conditions

Lifting Device (200-lb capacity)

0

Backhoe extended and lowered to ground

Materials/Parts

0

(TM 5-2420-231-10)

Cap Set, Protective, Dust and Moisture

0

Backhoe bucket removed (TM 5-2420-231-10)

0

(WP 0375, Item 4)

Estimated Time to Complete

Grease, Automotive and Artillery (GAA)

0

(WP 0375, Item 14)

1.0 hr

0

Rag, Wiping (WP 0375, Item 25)

0

WARNING

Allow hydraulic system to cool before performing procedure. Hot metal parts can cause

severe burns. Wear eye, hand, and skin protection when working with heated parts.

Hydraulic oil is very slippery. Immediately wipe up any spills.

Failure to follow these warnings may result in injury or death to personnel.

CAUTION

Plug and cap all hoses and fittings to prevent contamination. Failure to follow this caution

may result in damage to the machine.

NOTE

Tag and mark lines to aid in installation.

0276-1