TM 5-3805-255-14

0064

CLEANING AND INSPECTION CONTINUED

6. Inspect inlet valves, springs, and inlet valve seats for nicks, scratches, or cracks, and replace if necessary.

7. Inspect discharge valves, springs, and discharge valve seats for nicks, scratches, or cracks, and replace if

necessary.

8. Inspect discharge valve for leakage by applying 100 lb (45.36 kg) of air pressure through discharge port of

cylinder head and apply soap suds to discharge valve openings in floor of cylinder head. Leakage should not

exceed a 1-in. soap bubble within five seconds.

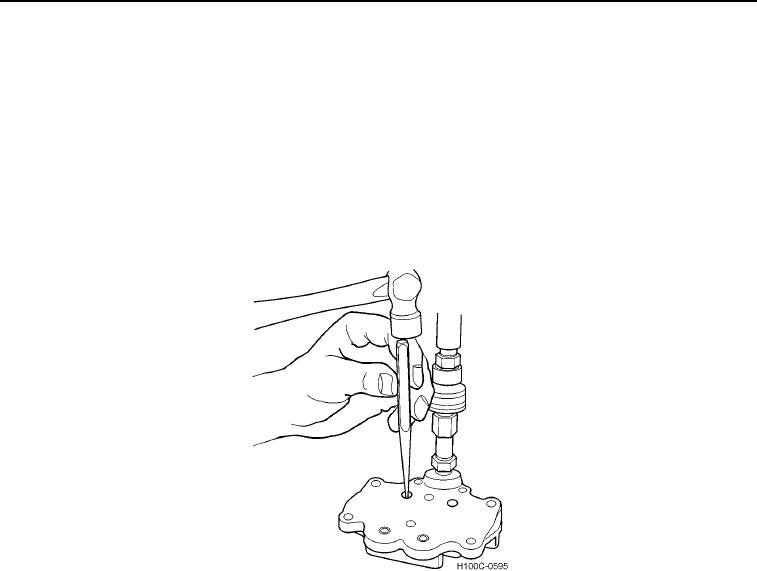

9. If excessive leakage is found, leave air pressure applied, and tap discharge valves off their seats several times

to improve seal between valves and their seats. If valves and seats have been reconditioned properly, this will

reduce leakage.

Figure 8. Seating Discharge Valve with Dowel.

0064

0064-10