TM 5-3805-255-14

0064

CLEANING AND INSPECTION CONTINUED

10. Inspect discharge valve caps for leaks by applying soap suds around the discharge valve caps with air

pressure applied as previously outlined. Leakage at valve caps is not permissible.

11. Check cylinder bores for evidence of excessive wear, out-of-round, or scoring. Replace parts as necessary.

12. Inspect pistons for scores, cracks, or wear, and replace if worn.

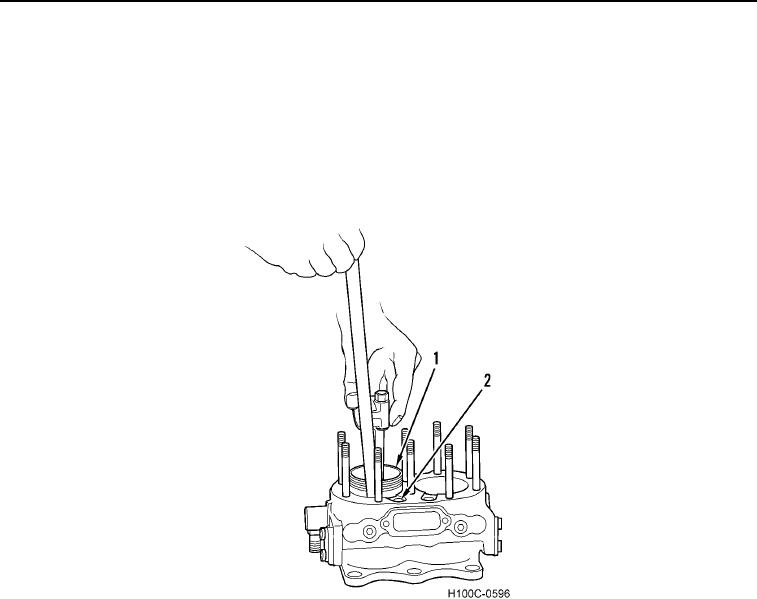

13. Inspect piston and cylinder bore clearance between pistons (Figure 9, Item 1) and cylinder bores (Figure 9,

Item 2) with feeler gauge stock. Clearance should be between 0.002 in. (0.101 mm) minimum and 0.004 in.

(0.101 mm) maximum.

Figure 9. Checking Piston and Cylinder Bore Clearance.

0064

0064-11