rpm as would be noticed when shifting lever into

5. Reinstall ball joint assembly in lever arm and

REVERSE position. A steady rpm will give a more

s e c u r e with locknut, then tighten jam nut on

p r o n o u n c e d indication. However, if forward

shift rod.

movement of the machine does occur, this is an

6. Check that levers will shift into all detent posi-

indication that the de-clutch valve is not func-

t i o n s without interference from the steering

tioning properly and must be replaced.

column, bell cranks, bell crank mounting sup-

3. Shut down engine and remove and replace de-

p o r t or transmission control cover and valve

clutch valve.

housing.

4 . Recheck valve operation as described in Steps

C h e c k Transmission De-Clutch Valve: The

1 and 2.

t r a n s m i s s i o n de-clutch valve is an air operated

valve consisting of a piston, piston stop plug, and

Check Converter Internal Pressure: The tor-

the necessary o-rings to provide an air tight body.

q u e converter internal pressure must be main-

This valve is installed in a housing bore containing

tained within the specified limits listed below to

a shut-off valve spool located in the transmission

i n s u r e proper operation of the torque converter

control cover and connected to the brake valve by

and converter regulator valve assembly.

a hose line.

Periodically check the converter internal pres-

The function of the de-clutch valve is to auto-

sure when fluid is at operating temperature

m a t i c a l l y establish a transmission neutral using

(180F. to 200F.) and engine operating at maxi-

air pressure from the brake system when the left

mum rpm.

brake pedal is applied.

1. Shut down engine and remove pipe plug from

When the left brake pedal is applied, the brake

converter regulator valve assembly.

valve releases air pressure from the brake system

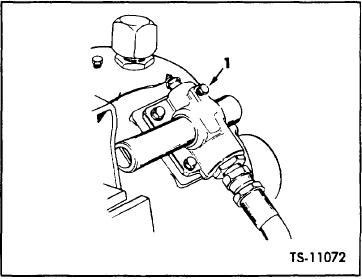

2. Install an accurate gauge (0 to 100 psi capacity)

into the de-clutch valve forcing the de-clutch valve

i n regulator valve pressure port as shown in

piston to contact the shut-off valve spool inside the

Figure 26, Item 1.

transmission control cover. This forces the shut-off

valve spool to shift into a position that prevents

3. Place directional lever in NEUTRAL and apply

o i l flow to the forward clutch, disengaging the

p a r k i n g brake.

clutch and establishing a transmission neutral. The

4. Start engine and accelerate to maximum rpm.

reverse clutch is not affected.

Gauge reading should be between a maximum

of 60 psi and a minimum of 30 psi.

This arrangement prevents the machine from

c r e e p i n g forward when loading or dumping the

If pressure is not within the specified limits,

bucket; yet permits backing away if operating on

further trouble shooting of the torque converter,

a sloping grade. It also increases the boom and

bucket hydraulic system working power by utiliz-

ing the power contained at the transmission, which

is normally used for engaging the forward clutch

to drive the wheels.

Maintenance consists of periodically checking

t h e de-clutch valve or proper operation as de-

scribed below :

1. Place directional shift lever in NEUTRAL position

and start engine.

2. Accelerate engine to approximately half throt-

tle, lightly apply left brake pedal and shift di-

rectional shift lever to FORWARD position. There

s h o u l d be no clutch engagement (causing the

m a c h i n e to move forward) or drop in engine

Fig.26.

Check Converter Internal Pressure

[45-05-2]