8. If bucket ROLLBACK and boom RAISE are not the

same within 50 psi, the circuit with the lower

r e a d i n g must have the relief valve cartridge

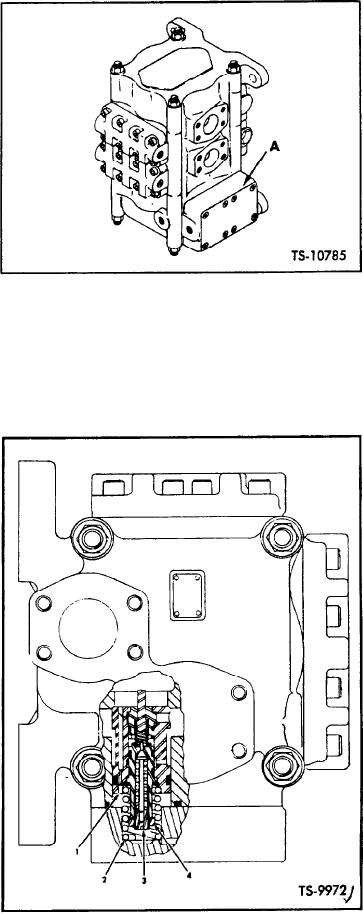

on the pilot valve changed. Figure 31 Item 1 is

bucket rollback cartridge Item 2 is boom raise

cartridge.

9. After either relief cartridge is changed, repeat

Steps 6,7,8 and 9 until recorded pressure read-

ings for bucket ROLLBACK and boom RAISE are

the same within 50 psi.

10. If gauge pressure readings or bucket ROLLBACK

and boom RAISE are the same within 50 psi, but

not to specification of 2200 50 psi, the main

relief valve, (located in the main control valve

Remove Cover - Main Relief

Fig. 32.

assembly) must be adjusted. See Steps 11 thru

13 for procedure.

15. With transmission directional lever in NEU-

TRAL, feather boom control lever to the DOWN

11. Remove eight bolts retaining cover (Figure 32,

PRESSURE position, maintaining low idle rpm.

Item A) and remove cover. Refer to Figure 33

Gauge should read 1750 to 2200 psi. If reading

a n d remove spring (Item 2) and main relief

is not as specified, replace down pressure relief

valve assembly (Item 1), which protrude from

v a l v e cartridge (Item 3 Figure 31).

face of main control valve after cover is re-

moved. Refer to Figure 33 and loosen hex lock-

nut portion (Item 4) of relief valve and turn

adjusting screw (Item 3) clockwise to increase

pressure or counter-clockwise to decrease pres-

s u r e . Each complete turn of adjusting screw

changes setting approximately 1600 psi. Exam-

ple : If pressure reading recorded in Step 9 was

1 4 0 0 psi, 1/2 turn (clockwise) of adjusting

screw would raise relief valve pressure to 2200

psi. After adjusting, tighten locknut.

12. Reinstall relief valve assembly and spring in

position in main valve assembly.

IMPORTANT: Adjusting screw and locknut

portion of relief valve must be toward outside

of valve.

13. Reinstall cover using two bolts in diagonally

o p p o s i t e holes in cover. Springs under cover

m u s t be compressed to start bolts into hole

t h r e a d s . Turn bolts finger tight. Install re-

maining bolts finger tight. Using a torque

wrench with adapter for 3/8 inch Allen wrench,

torque all bolts to 60-75 ft. lbs.

14. Place transmission directional and speed range

levers in FORWARD, HI, actuate bucket control

3. Adjusting Screw

Relief Valve Assy.

lever to full ROLLBACK position and accelerate

2. Spring

4. Locknut

to maximum rpm. Gauge should read 2200

5 0 psi..

Main Relief Valve

Fig. 33.

[45-05-5]