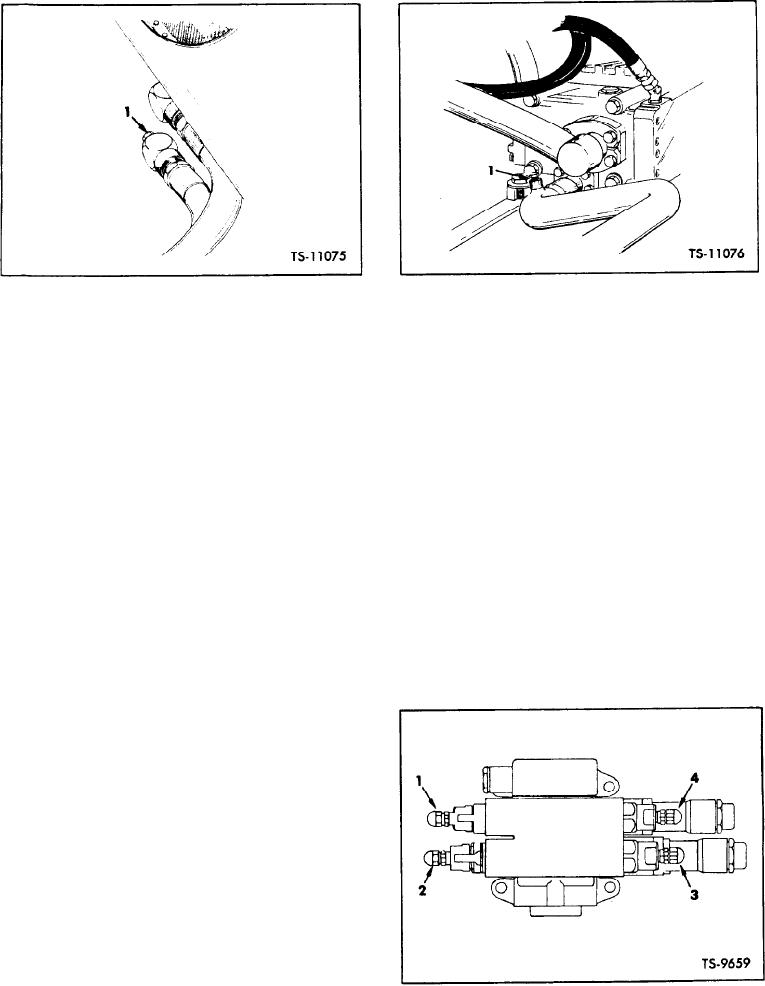

1. Pipe Plug

1. Pressure Port

Main Hydraulic Pressure Gauge Port

Fig. 30.

Check Pressure - Oil Cooler OUT

Fig. 29.

ure 30 for typical gauge installation.

3. With the aid of a helper, read gauges at steady

2000 rpm, and subtract oil cooler OUT Pressure

4 . Place transmission directional shift lever in

from oil cooler IN pressure to get pressure drop.

N E U T R A L , start engine and apply parking

Pressure drop should be between 10 psi and 30

brake.

psi.

5. If it is necessary during any of the following

steps to replace any of the relief valve cart-

If pressure difference equals or exceeds 30 psi

ridges on the pilot valve, remove seat and seat

it will be necessary to thoroughly clean or replace

support plate to gain access to pilot valve.

the oil cooler and/or the radiator assembly.

6. With transmission directional and speed range

levers in FORWARD, and HI, actuate bucket con-

Check Boom and Bucket Pressure: The boom

trol lever to ull ROLLBACK position and acceler-

and bucket hydraulic pump is coupled to the drive

a t e engine to maximum rpm. Record gauge

line and operates as soon as the engine starts. The

reading and proceed to Step 7.

pump draws fluid from the reservoir and forces it

under pressure into the main hydraulic valve, from

7. With transmission directional and speed range

which a small supply of fluid is directed to the pilot

levers in FORWARD, and HI, actuate boom con-

valve, routing the fluid back to the main valve, op-

trol lever to the full RAISE position and acceler-

erating the desired circuit in the main valve, sup-

a t e engine to maximum rpm. Record gauge

p l y i n g the flow of fluid to the cylinders. Preset

reading and proceed to Step 8.

overload relief cartridges on the pilot valve protect

the system and components.

Maintenance consists of periodically checking

the pressure in the system. All pressure checks are

to be made with fluids at operating temperature.

( 1 5 0 F . minimum),

1. Attach safety links and block wheels.

2. Use a hydraulic test gauge of at least 3000 psi

capacity. With engine shut down, loosen cap

o n hydraulic reservoir until pressure escapes,

t o minimize oil loss while attaching gauge,

then retighten cap.

3. Remove pipe plug from pressure port on main

pressure tube, and attach gauge. Refer to Fig-

Pressure Relief Cartridges - Pilot Valve

Fig. 31.

[45-05-4]