Engine Systems

Replace the filter as follows:

Fuel Tank

1. Unscrew the filter (or strainer) and discard it.

Refill the fuel tank at the end of each day's operation

to prevent condensation from contaminating the fuel.

2. Fill a new filter replacement cartridge about two-

thirds full with clean' fuel oil. Coat the seal gasket

CAUTION: A galvanized steel tank should never

lightly with clean fuel oil.

be used for fuel storage because the fuel oil

reacts chemically with the zinc coating to form

3. Install the new filter assembly and tighten it to two-

powdery flakes which quickly clog the fuel

thirds of a turn beyond gasket contact.

strainer and filter and damage the fuel pump

4. Start the engine and check for leaks.

and injectors.

AIR SYSTEM

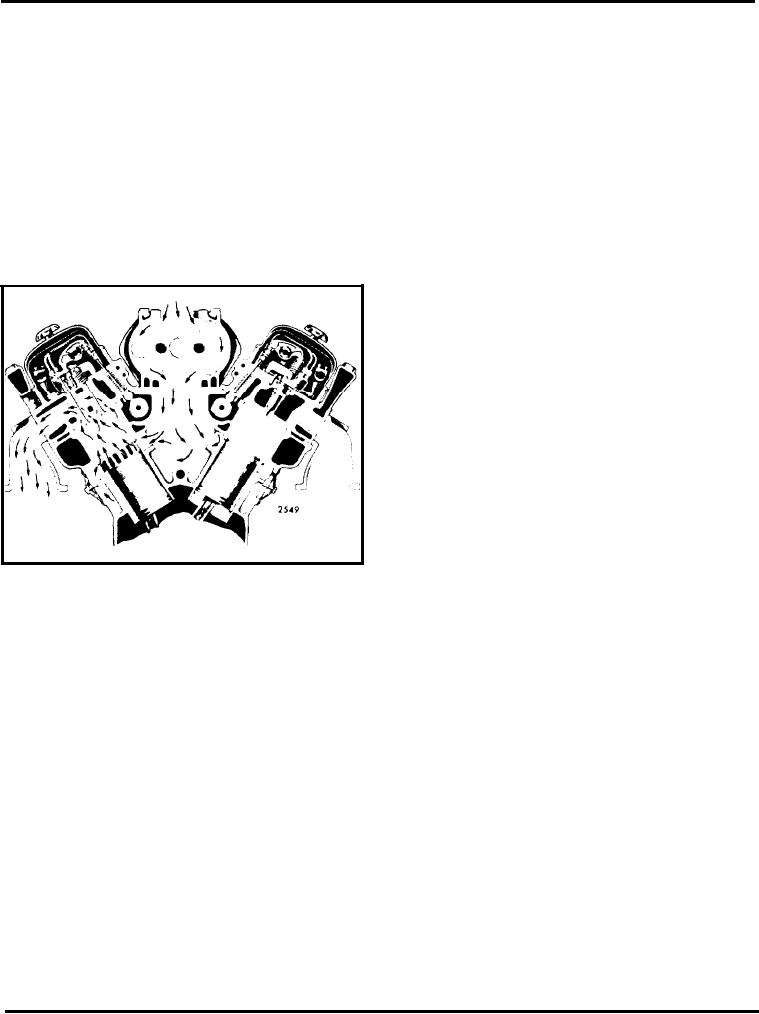

In the scavenging system used in two-cycle engines

and illustrated in Fig. 5, a charge of air, forced into

the cylinders by the blower(s), sweeps all of the

exhaust gases out through the exhaust valve ports,

leaving the cylinders filled with fresh air for

combustion at the end of each upward stroke of the

pistons. This air also helps to cool the internal engine

parts, particularly the exhaust valves. At the beginning

of the compression stroke, each cylinder is filled with

f r e s h , clean air which provides for efficient

combustion.

The blower(s) supplies fresh air required for

combustion and scavenging. The hollow three-lobe

rotors are closely fitted into the blower housing(s)

which is bolted to the cylinder block. The revolving

motion of these rotors pulls fresh air through the air

cleaner or silencer and provides a continuous and

uniform displacement of air in each combustion

Fig. 5 - Air Intake System Through Blower

chamber. The continuous discharge of fresh air from

and Engine

the blower creates a pressure in the air box (air box

pressure).

OIL BATH TYPE AIR CLEANERS

Several types of air cleaners are available for use with

A removable element assembly incorporated in the

heavy-duty oil bath air cleaners removes a major part

the V-71 engines. The light duty oil bath air cleaner

of the dust from the air stream thereby decreasing the

(Fig. 6) is used with some marine models and a light

dust load to the fixed element. An inner cup, which

or heavy duty oil bath air cleaner (Fig. 7) is available

can be removed from the outer oil cup, acts as a baffle

for industrial engines. Some engines are equipped

in directing the oil laden air to the element and also

with a heavy duty dry type air cleaner or a two-stage

controls the amount of oil in circulation and meters

dry type air cleaner (Fig. 8). The air cleaners are

the oil to the element. The oil cup supports the inner

designed for fast, easy disassembly to facilitate

cup, and is a reservoir for oil and a settling chamber

efficient servicing. Maximum protection of the engine

for dirt.

against dust and other forms of air contamination is

possible if the air cleaner is serviced at regular

intervals.

Service the light-duty oil bath air cleaner (Fig. 6) as

follows:

The oil bath air cleaner consists of the body and fixed

filter assembly which filters the air and condenses the

1. Loosen the wing bolt and remove the air cleaner

oil from the air stream so that only dry air enters the

assembly from the air inlet housing. The cleaner may

engine. The condensed oil is returned to the cup where

then be separated into two sections; the upper section

the dirt settles out of the oil and the oil is recirculated.

or body assembly contains the filter element and the

Page 16