Engine Systems

AIR SILENCER

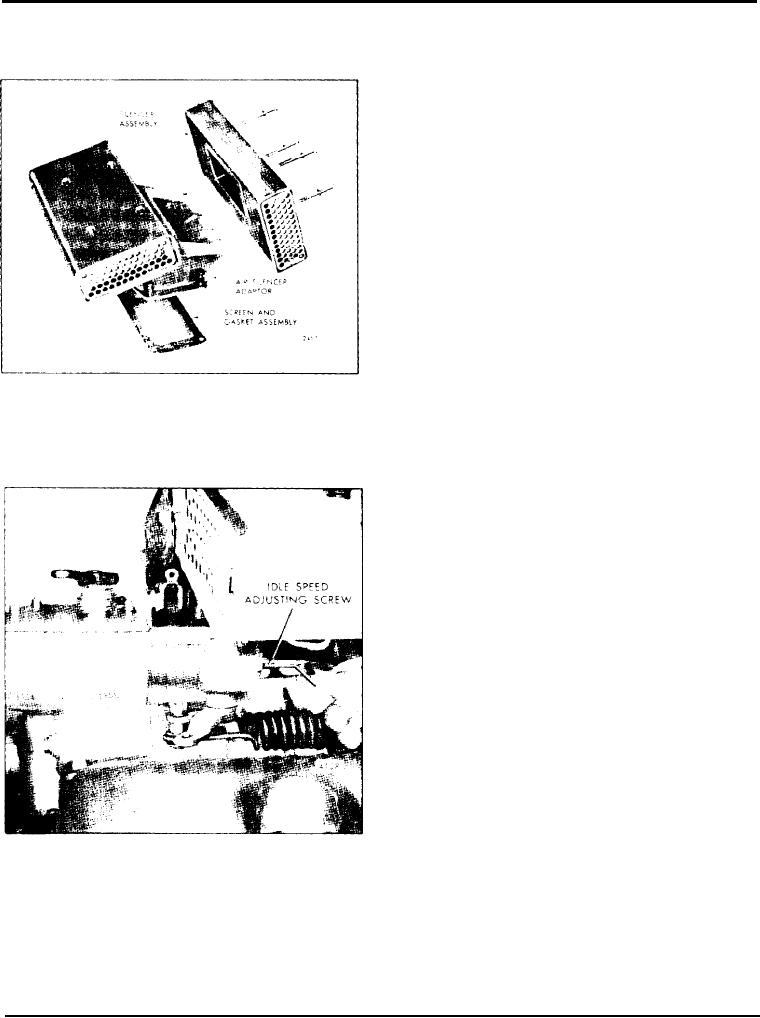

The air silencer (Fig. 11). used on some marine

models, is bolted to the air intake side of the blower

housing. The silencer has a perforated steel partition

welded in place parallel with the outside faces,

enclosing flame proof, felted cotton waste which serves

as a silencer for air entering the blower.

While no servicing is required on the air silencer

proper, it may be removed when necessary to replace

the air intake screen. This screen is used to filter out

any large foreign particles which might seriously

damage the blower assembly.

Fig. 11 - Silencer Assembly

AIR BOX DRAINS

In normal operation, a slight amount of vapor from

the air condenses and settles at the bottom of the air

box. This condensation is drained through air box

drain tubes (Fig. 12) which direct the expelled air and

vapor down and away from the engine.

Air box drains must he open at all times, otherwise

water and oil may accumulate in the air box and be

drawn into the cylinders with the incoming fresh air.

Therefore, periodic checks should he made to ensure

they are open. Remove the air box covers and examine

the air box floor for oil or an accumulation of water. If

oil or water is found, wipe the air box dry with clean

rags and remove and clean the air box drain tubes.

Fig. 12 - Air Box Drains

Page 20