Check brake linings for wear, cracks, and oil satura-

Oil Seals, Gaskets and Retaining Rings

tion. If linings are worn to within 1/16" of retaining bolts

Replacement of spring loaded oil seals, gaskets and

or otherwise damaged, replace brake linings.

snap rings is more economical when unit is disassembled

Check cam shaft brake spider bushings and brake

than to risk premature overhaul to replace these parts at

chamber bracket bushings for wear, cracks, distortion, or

a future time. Loss of lubricant through a worn seal may

other damage. If inside diameter is worn beyond dimen-

result in failure of other more expensive parts of the

sions indicated in Brake Wear Limits Chart, replace bush-

assembly. Sealing members should be handled carefully,

ings.

particularly when being installed. Cutting, scratching, or

Inspect brake drums for cracks, heat checks, scoring, or

curling under of lip of seal seriously impairs its efficiency.

other damage. Turn down on lathe if necessary. If drum

At reassembly, lubricate lips of oil seals with Lubriplate.

diameter exceeds dimensions indicated in Brake Wear

Limits Chart, replace drum.

Gears and Shafts

Replace brake shoe return springs each time axle is

If magna-flux process is available, use process to

overhauled.

check parts. Examine teeth and ground and polished

surfaces on all gears and shafts carefully for wear, pitting,

BRAKE WEAR LIMITS CHART

chipping, nicks, cracks or scores. If gear teeth are cracked

or show spots where case hardening is warn through,

20x5

161/2 x 6

ITEM

20x7

replace with new gear. Small nicks may be removed with

suitable hone. Inspect shafts to make certain they are not

1.228"

Anchor Pins-O. D.

1.478"

sprung, bent, or splines twisted, and that shafts are true.

16.750"

Brake Drum-Max. Rebore

20.250"

Differential pinions and side gears must be replaced as

1.263"

1.513"

Broke Shoe Bushings-l. D.

sets. Differential ring gear and bevel pinion must also be

1.526"

1.526"

Camshaft Bushings-l. D.

replaced as a set if either is damaged.

1.469"

1.469"

Camshaft-O. D.

.770"

Cam Roller-l. D.

.895"

Housing and Covers

.735"

Cam Roller Pin-O. D.

,859"

Inspect housing, covers and planet spider, and differen-

tial case to be certain they are thoroughly cleaned and

Parking Brake

that mating surfaces, bearing bores, etc., are free from

Inspect brake backing plate for distortion. Check that

nicks or burrs. Check all parts carefully for evidence of

cam levers on backing plate swivel freely, but that mount-

cracks or conditions which would cause subsequent oil

leaks or failures.

ing rivets are firmly seated in plate. Replace backing

plate if damaged or if cam levers are loosely mounted.

Inspect brake linings for grease saturation, wear, or

Service Brakes

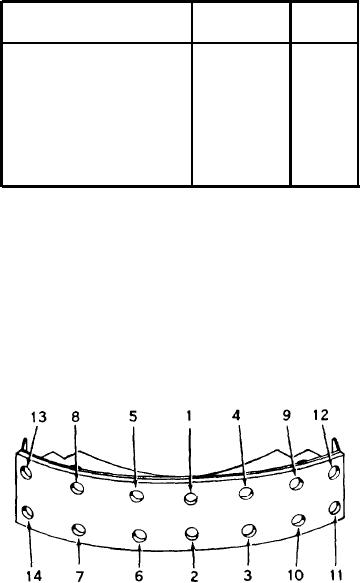

looseness. Replace if worn to less than 5/32 inch. Rivet

Inspect anchor pins for wear or damage. If they are

new brake linings to shoes following sequence indicated

worn beyond dimensions indicated in Brake Wear Limits

in Fig. 87.

Chart, or if they are pitted, scored or deeply nicked, re-

place anchor pins.

Check brake shoe bushings for wear. If inside diameter

exceeds dimensions indicated in Brake Wear Limits Chart,

replace bushings.

Check cam roller for wear and distortion. If inner diam-

eter is worn beyond dimensions indicated in Brake Wear

Limits Chart, or if outer diameter has flat spot more than

1/4 inch wide extending across roller, replace rollers.

Check cam roller pins for wear and corrosion. If worn

beyond dimensions indicated in Brake Wear Limits Chart,

or if pitted, scored, or deeply nicked, replace cam roller

pins.

TS-6219

FIG. 87

Inspect cam shafts for wear or corrosion of bearing sur-

Inspect brake drums for cracks, heat checks, scoring, or

faces. If worn beyond dimensions indicated in Brake Wear

other damage. Turn down on lathe if necessary. If drum

Limits Chart, or if bearing surfaces are pitted, scored, or

diameter exceeds 13.340 inches, replace drum.

deeply nicked, replace cam shafts.

[31]