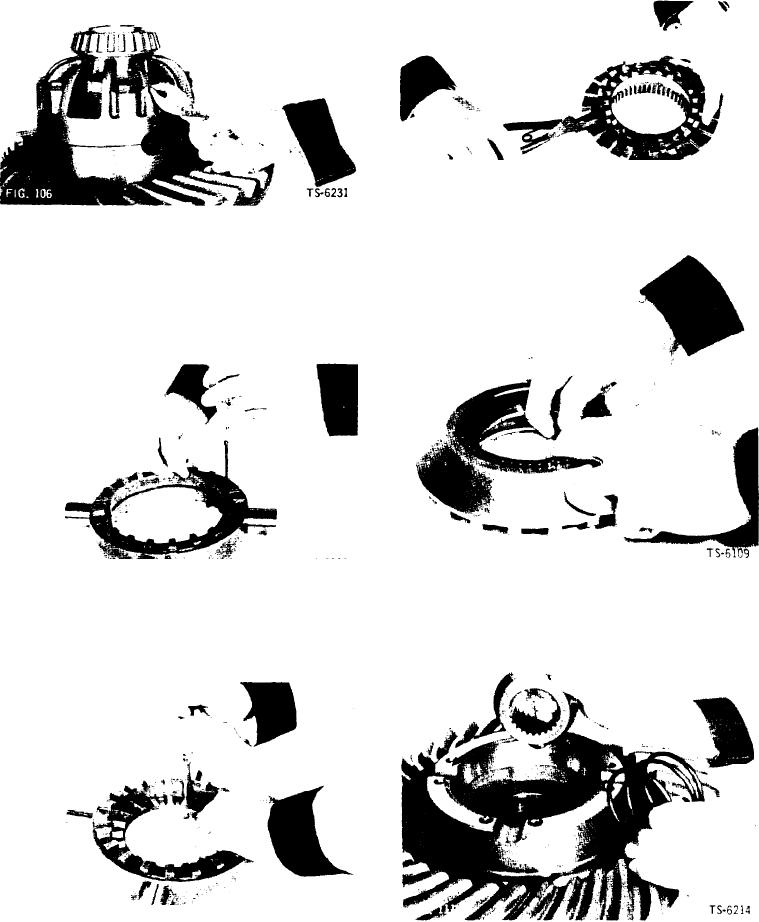

4. Lockwire bolts in pairs (Fig. 106) on axles that use

3. Install holdout ring on drive clutch with snap ring pliers

tapped differential case bolt holes.

(Fig. 109).

FIG. 109

TS-6116

4. Install spring retainer in driven clutch (Fig. 110).

Reassembly of No SPlN Differential

NOTE: lightly lubricate parts of No SPlN differential

during assembly. Special lubricants are not required

for use with this differential.

1. Install snap ring in internal groove of spider (Fig. 107).

FIG. 110

FIG. 107

TS-6113

2. Position center corn in spider. Spread snap ring while

5. Install side gear and spring in differential case half

inserting center cam (Fig. 108). Make sure center cam

(Fig. 111).

ring groove is fully engaged by snap ring to retain

center cam.

FIG. 106

TS-6115

[36]