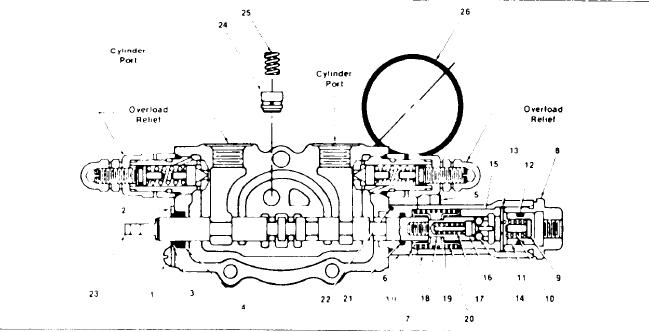

PILOT VALVE PLUNGER SECTION

Install O-rings (21) in cap spacer (6) and slide

INSPECTION

over plunger. Place tang end of plunger in a vise.

Assemble one spring seat (19) over plunger end.

Clean all parts including housing in solvent and

Install plunger spring (20) second spring seat (19)

dry with compressed air. Inspect seal counter

and thread detent pin (18) in the plunger. Slight

bores, they must be free of nicks and contamina-

pressure will be required to compress the plunger

tion. Examine all springs for breaks or distortion.

spring.

Inspect sliding surfaces of piston (11) and pilot

Apply grease to cross holes of detent pin (18) to

plug (8) for nicks, scores or excessive wear. With

hold balls (14) in place. Insert detent spring (17) in

O-ring (12) removed insert piston (11) in the pilot

cam (16).

plug (8) and test for fit. Piston (11) must fit freely

Slide detent sleeve (15) into plunger cap (7) and

w i t h o u t binding through a complete revolution.

place as an assembly over a drive pin or punch.

I n s p e c t O-ring grooves in piston (11) and cap

U s i n g this punch or drive pin depress cam (16)

spacer (6). These surfaces must be free from nicks

w i t h detent spring (17) and insert balls (14) into

and contamination. Examine all O-rings for dam-

detent pin (18) cross holes. Guide detent sleeve

age or deterioration. Any parts found to be defec-

(15) and plunger cap (7) as an assembly over the

tive must be replaced.

detent pin (18). Continue to insert detent sleeve

Examine face of load check poppet (24) and cor-

(15) until it contacts spring seat (19).

r e s p o n d i n g seat in plunger section housing for

Assemble O-ring (12) pin (9) spring (10) and in-

nicks or scratches. If minor scratches are present

sert as an assembly into pilot plug (8). Install spac-

the poppet should be lapped to seat properly. Use

er (13) in plunger cap (7) and thread pilot plug (8)

fine lapping compound and exercise extreme care

assembly into plunger cap (7).

to prevent lapping compound from entering or re-

maining in the valve. Check valve poppet (24) must

Assemble O-ring (4), wiper (3), seal plate (2) and

fit loosely in housing.

secure with machine screws (1). Insert load check

p o p p e t (24) and corresponding spring (25) be-

Test plunger (23) for fit in its respective bore.

tween sections along with O-ring seal (26).

The plunger must be free of score marks and must

fit snugly without binding through a complete revo-

S t a c k inlet, plunger and end cap sections to-

lution.

gether. Be sure O-ring seals (26) between sections

Inspect service port relief seats in section hous-

are properly positioned.

ing. They must be free of nicks or grooves.

Install three tie rods and tighten nuts. A torque

wrench should then be used to apply 14 ft. lb. (1,94

ASSEMBLY

kg. mtrs.) to the two 5/16" (7,9 mm) diameter tie rods

Coat

all parts including housing bores with hy-

and 33 ft. lb. (4.56 kg. mtrs.) to the one 3/8" (9,5 mm)

draulic

oil. Begin reassembly of the valve with

diameter tie rod. Install sectional control valve as-

plunger

sections. Since the internal parts are simi-

sembly on machine and reassemble associated

lar, the

assembly procedure pertains to both.

plumbing.

[ 36 ]