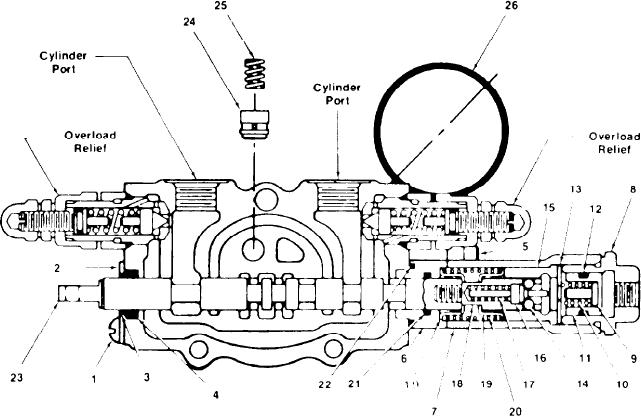

PILOT VALVE PLUNGER SECTION

DISASSEMBLY

Remove two socket screws (5) securing spacer (6)

and plunger cap (7). Slide the plunger as a com-

With the exception of the valve plunger and

plete assembly from the section housing. With a

plunger housing, all parts are considered field ser-

firm grip on the plunger cap (7) unscrew pilot

viceable. Should either plunger or housing be de-

plugs (8) and remove pin (9), spring (10), pistons

fective, it is recommended to replace the complete

(11), O-ring (12) and spacer (13). Place tang end

plunger section. If any emergency situation neces-

of plunger (23) in a vise. To prevent losing the de-

sitates field repair of the plunger or section hous-

tent balls (14) wrap a cloth around the plunger cap

ing, refer to the emergency repair instructions.

(7) and with a swift jerk remove the plunger cap

(7). Remove detent sleeve (15), balls (14), cam (16)

The internal parts of the boom and bucket plung-

and spring (17). Insert a rod through the cross hole

er sections are similar therefore this disassembly

in the detent pin (18) and unscrew it from the plung-

procedure pertains to both. Begin disassembly by

er. Slight pressure should be exerted against the

removing the cylinder port relief valve from plung-

detent pin (18) as it disengages and spring tension

er sections. Proceed to service the section by re-

is released. Remove spring seats (19) plunger

moving machine screws (1), seal plate (2), wiper

spring (20), cap spacer (6) and two O-rings (21 &

(3) and O-ring (4) from the tang end of plunger.

22) from the cap spacer.

[34]