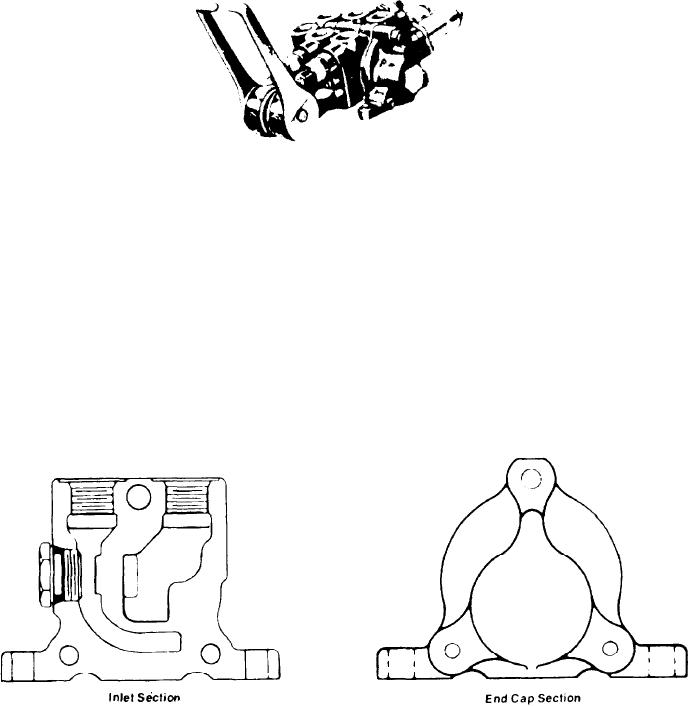

DISASSEMBLY, ASSEMBLY AND

INSPECTION OF THE PILOT

C O N T R O L VALVE

PREPARATION FOR REMOVAL OF

DISASSEMBLY

VALVE FROM MACHINE

Remove the three tie rod nuts from one side of

Thoroughly clean the outside of the valve. To

the valve. Before removing tie rods and separating

insure accurate reassembly of the valve, tag all

sections, caution must be observed to avoid losing

inlet, end cap and control ports prior to removing

load check poppets and springs which are enclosed

the valve from the machine. Prepare a clean and

between the sections. Tag the check poppets

a d e q u a t e work area before disassembling. Re-

with respect to their plunger section. An O-ring is

move valve from machine and position on mount-

also present between the sections.

ing pads.

Slide the three tie rods from the valve and sep-

a r a t e sections. Remove check poppet (24) spring

Care must be exercised to protect all machined

(25) and O-ring seal (26). (See below)

surfaces.

surface using fine lapping compound. Clean sec-

M a i n t e n a n c e of the inlet and end cap section

tion thoroughly when finished. Remove plugs and

consists of visually inspecting the machined seal-

O-rings from inlet section. Examine O-rings for

ing surfaces for scratches or nicks. If present, re-

damage or deterioration. Replace if necessary.

move by lapping on a perfectly smooth flat steel

[ 33 ]