TM 5-3805-258-24-1

P O W E R T R A IN

S Y S T E M S O P E R A T I O N

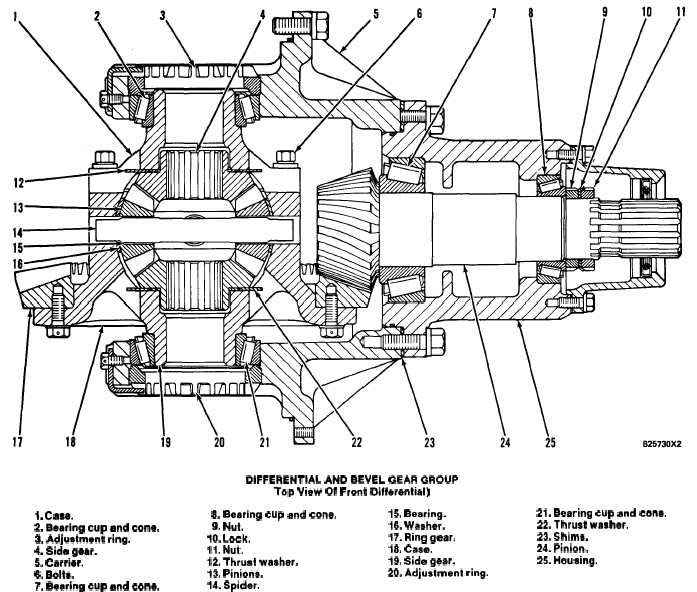

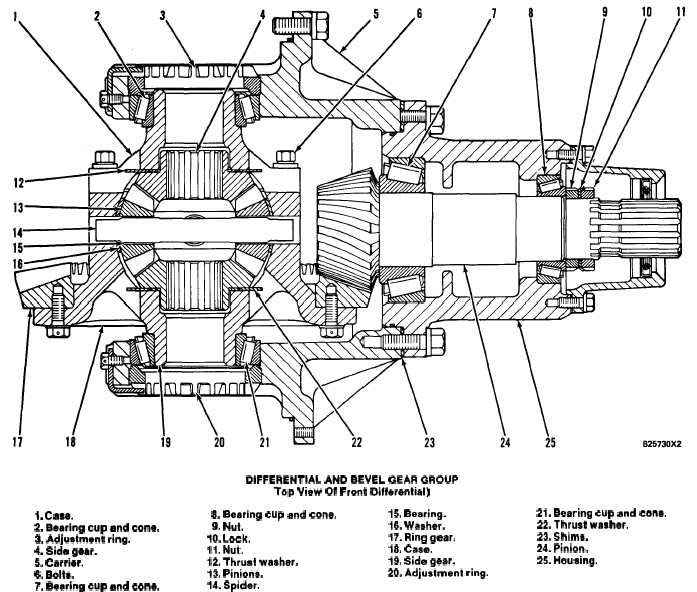

DIFFERENTIALS

DIFFERENTIAL AND BEVEL GEAR GROUP

Top View Of Front Differential)

1. Case.

8. Bearing cup and cons.

2. Bearing cup and cone.

9. Nut.

3. Adjustment ring.

10. Lock.

4. Side gear.

11. Nut.

5. Carrier.

12. Thrust waahar.

6. Bolts.

13. Piniona.

7. Bearing cup and cone.

14. Spider.

A differential divides or causes a balance of the

power which is sent to the wheels. When one wheel

turns slower than the other, as in a turn, the differen-

tial lets the inside wheel go slower in relation to the

outside wheel. The differential still sends the same

amount of torque to each wheel.

Bevel pinion (24) is connected to a yoke. The yoke

assembly is connected to a universal joint from the

output transfer gears. Pinion (24) is connected to the

yoke assembly by splines. Pinion (24) is engaged with

ring gear (17). Ring gear (17) is fastened to the

differential group. Differential carrier (5) is fastened

to the axle housing.

15. Bearing.

21. Bearing cup and cons.

16. Waaher.

22. Thrust waaher.

17. Ring gear.

23. Shims.

18. Case.

24. Pinion.

19. Side gear.

25. Housing.

20. Adjustment ring.

The differential group has a case (18). Ring gear

(17) is fastened to case (18). Case (18) is fastened to

case (1) by bolts (6). Inside the differential group is

side gear (4), spider (14), four pinions (13) and side

gear (19). Spider (14) is installed between the two

cases. When the cases are turned, the spider turns.

Pinions (13) are installed on the spider and are en-

gaged with the teeth of side gears (4 and 19). The

axle shafts are connected to the side gears by splines.

Side gears (4 and 19) turn against thrust washers (12

and 22). Pinions (13) turn on bearings (15).

Nuts (9 and 11) and lock (10) are used to make an

adjustment to the end play (bearing preload) of bear-

ings (7 and 8) for pinion (24).

3-52