TM 5-3805-258-24-1

POWER TRAIN

NOSPIN DIFFERENTIAL GROUP

S Y S T E M S O P E R A T I O N

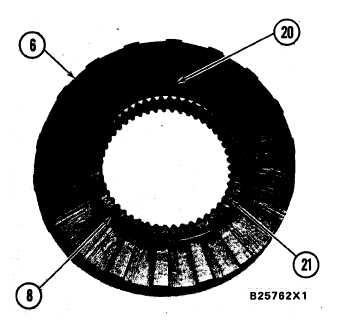

CLUTCH AND HOLDOUT RING

6. Driven clutch. 8. Holdout ring. 20. Notch in holdout

ring. 21. Cam.

OPERATION OF NOSPIN DIFFERENTIAL

When a wheel is made to turn faster than the speed

of the bevel gear, the “clutch action” (the stopping of

power to drive axle) of the NoSpin differential will

let this axle turn faster than the speed of the bevel

gear.

The “clutch action” of the NoSpin differential is

as follows: If spider (17) turns, spider key (19) lo-

cates center cam (15) and the spider and the center

cam turn at the speed of the bevel gear. The center

cam turns holdout ring (8) and cam (21) at the speed

of the bevel gear. The spider turns driven clutch (6)

at the speed of the bevel gear. The driven clutch turns

the side gear, axle and wheel at the speed of the bevel

gear.

When the wheel is made to turn faster than the

speed of the bevel gear, the teeth of center cam (15)

work like ramps and the teeth of cam (21) move up

the teeth of the center cam. This action causes driven

clutch (6) to become disengaged (not engaged) with

the spider. The driven clutch pulls holdout ring (8)

out of the grooves in the center cam. The friction

between the holdout ring and driven clutch turns the

holdout ring until notch (20) in the holdout ring

engages with spider key (19). The holdout ring is now

turned by the spider key at the speed of the bevel

gear. The teeth of the holdout ring are now in a

position so they can not engage the notches in the

center cam. The driven clutch and cam move around

the holdout ring at a speed faster than the speed of

the bevel gear. The holdout ring keeps the driven

clutch and cam from being engaged (engagement)

with the center cam and spider. The driven clutch,

cam, axle shaft and wheel now turn freely.

The opposite side clutch, cam and holdout ring are

held engaged to the center cam and spider by spring

(7) as long as the driven wheel turns slower.

When the speed of the wheel that is not engaged

becomes slower and near the speed of the bevel gear,

the resistance of the ground to the wheel causes the

torque on this wheel to be in a small reverse direction.

This causes the driven clutch and cam to turn in a

direction opposite the direction of the bevel gear. The

friction between the holdout ring and the driven

clutch causes the holdout ring to move in a direction

opposite the direction of the bevel gear. Notch (20) in

the holdout ring moves away from spider key (19).

When the teeth of the holdout ring are in a position to

engage the notches in center cam (15), the force of

the spring causes the driven clutch and cam to move

to the inside. The driven clutch pushes the holdout

ring. The holdout ring now engages the center cam

and is turned at the speed of the bevel gear. The teeth

of cam (21) now engage the center cam and the teeth

of the drive clutch engage the spider. At this time,

both wheels are turned at the same speed.

NOTE: When both wheels are turned at the same

speed they do not necessarily have equal torque. For

example: When one wheel starts to turn faster on ice

(tends to spin), both clutches engage and both wheels

turn at the same speed. The wheel that is on ice will

have less torque.

3-56