F U E L S Y S T E M

TM 5-3805-258-24-1

T E S T I N G A N D A D J U S T I N G

that follow to determine if the nozzle performance is

acceptable.

I.

II.

III.

IV.

V.

Valve Opening Pressure Test.

Flush the Nozzle.

Tip Leakage Test.

Orifice Restriction Test.

Bleedscrew Leakage Test.

Nozzle Preparation for Test

Before fuel injection nozzle (1) can be tested, all

loose carbon around the tip of the nozzle must be

removed with the 8S2258 Brass Wire Brush (M).

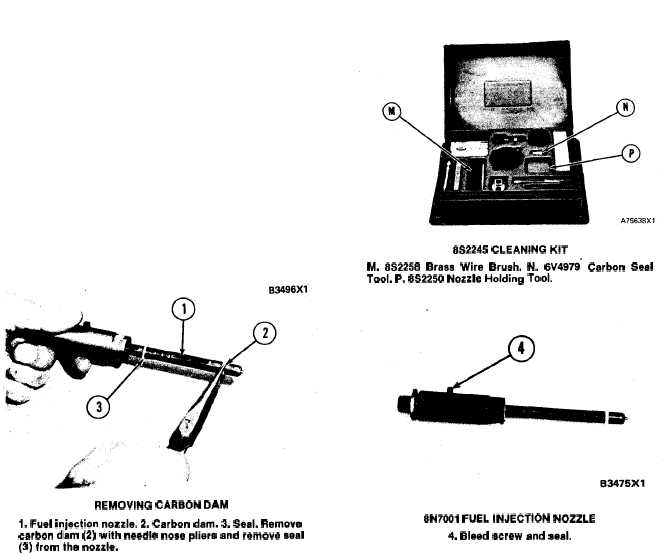

REMOVING CARBON DAM

1. Fuel injection nozzle. 2. Carbon dam. 3. Seal, Remove

carbon dam (2) with needle nose pliers and remove seal

(3) from the nozzle.

CAUTION

Do not use a steel brush or a wire wheel to clean

the nozzle body or the nozzle tip. Use of these

tools can cause a small reduction of orifice

size, and this will cause a large reduction in

engine horsepower. Too much use of the

8S2258 Brass Wire Brush will also remove the

coating that is on the nozzle for protection.

Clean the groove for carbon seal dam (2) and the

body of the nozzle below the groove with the 8S2258

Brass Wire brush (M). Remove the carbon, but be

sure not to use the brush enough to cause damage to

the body of the nozzle.

NOTE: A change in color in the area below the

groove is normal and does not effect the body of the

nozzle.

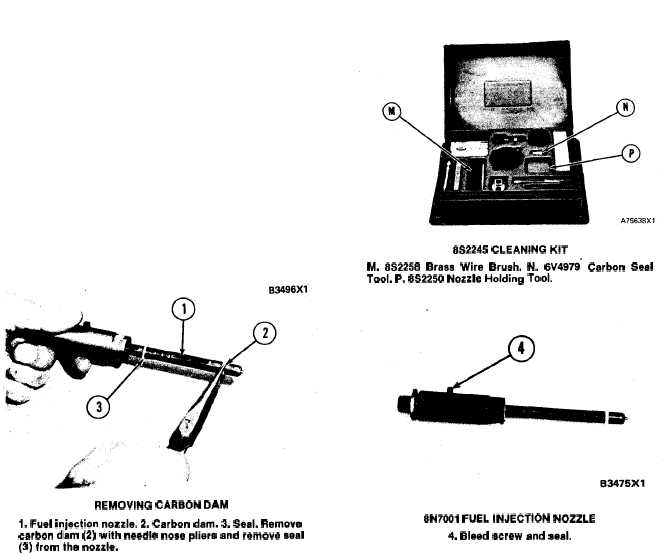

8S2245 CLEANING KIT

M. 8S2258 Braas Wire Brush. N. 6V4979” Carbon Seal

Tool. P. 8S2250 Nozzle Holding TOOL

8N7001 FUEL INJECTION NOZZLE

4. Bleed screw and seal.

Remove bleed screw and seal (4) from the nozzle.

NOTE: The bleed screw and seal must be removed

for all tests except test V; Bleed Screw Leakage Test.

I. Valve Opening Pressure Test (VOP)

1.

2.

Install 6V2170 Tube Assembly (C) to the tester.

Install 8N7001 Fuel Injection Nozzle with

5P7448 Adapter (A) on tube assembly (6). Posi-

tion the bleed screw hole toward the tester and in

line with 6V2170 Tube Assembly (C). This will

make the fuel spray pattern horizontal. Be sure

the nozzle tip is down and extends into FT1384

Extension (F) and 8S2270 Fuel Collector (J).

4-7