TM 5-3805-258-24-1

F U E L S Y S T E M

T E S T I N G

A N D

A D J U S T I N G

in the lifter. Install the fuel injection pump

straight down into the bore.

F U E L

P U M P

I N S T A L L A T I ON

( T Y P I C A L

E X A M P L E)

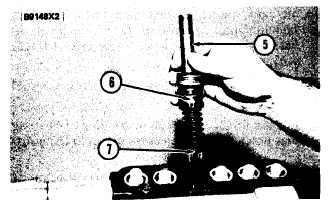

5. 8S2244 Extractor. 6. Groove of barrel. 7. Fourth tooth

of gear segment.

6. Push down on extractor (5) (hand force only) and

install O-ring and bushing that holds the injec-

tion pump in the pump housing. If the pump is

in the correct position, the bushing will turn into

the threads of the fuel injection housing with the

fingers until it is even with the top of the hous-

ing. When the bushing is installed correctly,

tighten the bushing to 160 ± 14 N·m (120 ± 10

lb. ft.).

CAUTION

The bushing must be tightened to the correct

torque. Damage to the housing will be the re-

sult if the bushing is too tight. If the bushing is

not tight enough, the pump will have leakage.

7.

8.

9.

Install the fuel injection line to the pump and

tighten to 40 ± 7 N·m (30 ± 5 lb. ft.).

Remove timing pin (4) and install timing pin

cover (3).

Install fuel filter base and filter (1) and fuel

line (2).

WARNING

If one or more of the fuel injection pumps have

been installed wrong, it is possible for the en-

gine to run out of control when started. When

any of the fuel injection pumps have been re-

moved and installed, take the precautions

(steps) that follow to stop the engine if it starts

to overspeed (run out of control).

a. Remove the air cleaner pipe from the turbo-

charger and leave the air inlet for the turbo-

charger open.

b. Set the governor at low tide.

Be careful when

opening. Due to

WARNING

plate is put against air inlet

excessive suction, the plate

can be pulled quickly against air inlet open

ing. To avoid crushed fingers, do not put fingers

between plate and air inlet opening.

S T O P P I N G T H E E N G I N E ( T Y P I C A L E X A M P L E )

c. Start the engine, and if engine starts to over-

speed (run out of control) put a steel plate

over the air inlet to stop the engine.

4-12