TM 5-3805-258-24-1

F U E L S Y S T E M

T E S T I N G A N D A D J U S T I N G

When fuel injection nozzles are tested, be

sure to wear eye protection. Test fluid

comes from the orifices in the nozzle tip with

high pressure. The test fluid can pierce (go

thru) the skin and cause serious injury to the

operator. Keep the tip of the nozzle pointed

away from the operator and into the 8S2270

Fuel Collector and FT1384 Extension.

N O Z Z L E R E A D Y F O R T E S T

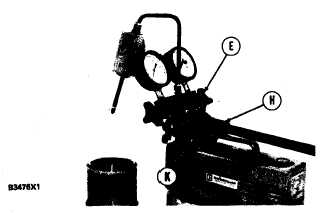

E. Gauge protector valve. H. On-off valve. K. Pump isola-

tor valve.

CAUTION

Put a shop towel around the upper part of

the nozzle to take in any fluid leakage.

3. Close on-off valve (H). Open pump isolator

valve (K).

4. Open gauge protector valve (E). Operate the

pump to make a slow increase in pressure until

the valve in the fuel injection nozzle just starts to

open. Read the maximum gauge pressure at the

instant fluid flows from the tip.

NOTE: It is possible for the pressure reading of the

gauge to go down fast if the valve makes a noise

(chatters) when it opens. It is also possible for the

pressure reading of the gauge to be almost constant

when the valve in the fuel injection nozzle opens.

NOTE: The valve in the fuel injection nozzle can be

good and still not make a noise (chatter), or not have

a very fine vapor (spray) from the orifices in the tip of

the fuel injection nozzle during Step 4.

If the opening pressure is not within specifications,

do not use the fuel injection nozzle again.

VALVE OPENING PRESSURE (VOP) SPECIFICATIONS

8300 to 16200 kPa

(1200 to 2350 psi)

Il. Flush the Nozzle

1. Close gauge protector valve (E). Close on-off

valve (H). Open pump isolator valve (G).

NOTE: Make sure nozzle extends inside and below

the top of FT1384 Extension (F).

2. Operate the pump rapidly for three full strokes.

III. Tip Leakage Test

1.

2.

Remove all fluid from the nozzle tip and body

with a clean cloth.

Put a clean cloth around the body of the nozzle to

take in any leakage from the bleed screw hole

and prevent any fuel leakage to drain down to

the tip of the nozzle.

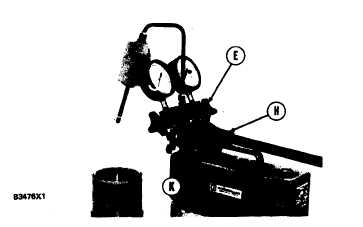

N O Z Z L E R E A D Y F O R T E S T

E. Gauge protector valve. H. On-off valve. K. Pump isola-

tor valve.

3.

4.

Open gauge protector valve (E). Close on-off

valve (H). Open pump isolator valve (K).

Make and hold for 15 seconds a pressure of 1380

kPa (200 psi) less than the opening pressure

measured in VOP Test I and make a note of the

number of drops that fall.

TIP LEAKAGE SPECIFICATION

No more than 5 drops can fall in 15 seconds.

4-8