F U E L

S Y S T E M

5. If the nozzle is not within specifications, DO

NOT USE THE NOZZLE.

IV. Orifice Restriction Test

1.

2.

3.

Close gauge protector valve (E) and on-off valve

(H). Open pump isolator valve (K).

Point the tip of the fuel injection nozzle into the

8S2270 Fuel Collector and FT 1384 Extension.

Be sure the bleed screw hole is positioned toward

the tester and is in line with 6V2170 Tube As-

sembly (C). This will make the fuel injection

nozzle be 15° from vertical and the spray pat-

tern will be horizontal.

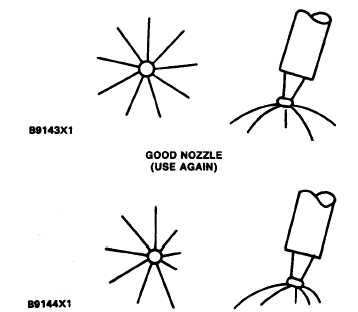

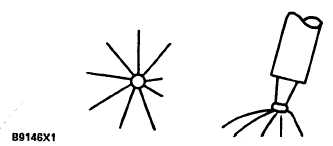

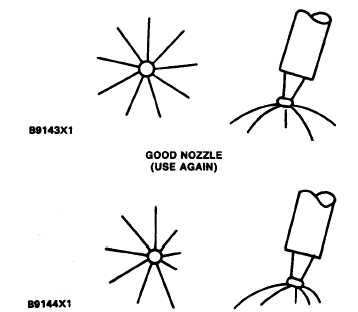

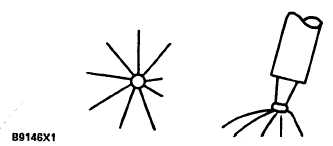

Make a slow increase in pressure and look at the

orifice discharge pattern (shape of discharge)

when fluid begins to flow through the fuel injec-

tion nozzle. The discharge must be the same

through all nine orifices. Any change either ver-

tically or horizontally, is an indication of a bad

nozzle.

T Y P I C A L D I S C H A R G E P A T T E R N F O R O R I F I CE

W I T H A R E S T R I C T I ON

( R E P L A C E M E N T

N E C E S S A R Y )

T Y P I C A L

D I S C H A R G E

P A T T E R N

W I T H

H O R I Z O N T A L

D I S T O R T I O N

( R E P L A C E M E N T

N E C E S S A R Y )

TM 5-3805-258-24-1

T E S T I N G

A N D

A D J U S T I N G

T Y P I C A L D I S C H A R G E P A T T E R N W I T H V E R T I C A L

D I S T O R T I ON

( R E P L A C E M E N T

N E C E S S A R Y)

V. Bleed Screw Leakage Test

1. Install bleed screw and seal (4) in fuel injection

nozzle. Tighten the bleed screw to a torque of

1.8 ± 0.2 N·m (16 ± 2 lb. in.).

CAUTION

Do not tighten the bleed screw more than the

torque shown. The bleed screw or seal can be

damaged.

2.

3.

4.

Put the tip of the fuel injection nozzle down

inside the 8S2270 Fuel Collector and FT1384

Extension.

Close on-off valve (H). Open gauge protector

valve (E) and pump isolator valve (K).

Pump the tester until fuel injection nozzle is full

of fluid and the pressure on-the gauge is 27500

kPa (4000 psi).

NOTE: 15 or 20 strokes of the pump can be neces-

sary for the pressure to get to 27500 kPa (4000 psi).

BLEED SCREW LEAKAGE SPECIFICATION

There must be no leakage between the bleed screw and

the body of the fuel injection nozzle.

5. If there is leakage, replace the 1W8616 Seal.

Inspect the washer face of the bolt for damage,

replace if needed. Test the nozzle again. If there

is still leakage, the fuel injection nozzle must be

replaced.

6. If no fuel leakage is found, the fuel injection

nozzle is acceptable. Put a new seal (3) on the

nozzle. Install a new carbon dam (2) in nozzle

groove with 6V4979 Carbon Seal Tool (N).

4-9