TM 5-3805-258-24-1

A I R I N L E T A N D E X H A U S T S Y S T EM

T E S T I N G A N D A D J U S T I NG

AIR INLET AND EXHAUST SYSTEM

RESTRICTION OF AIR INLET

AND EXHAUST

There will be a reduction of horsepower and effi-

ciency of the engine if there is a restriction in the air

inlet or exhaust system.

Air flow through the air cleaner must not have a

restriction of more than 762 mm (30 in.) of water

difference in pressure.

Back pressure from the exhaust (pressure differ-

ence measurement between exhaust outlet elbow and

atmosphere) must not be more than 686 mm (27 in.)

of water.

MEASUREMENT OF PRESSURE

IN INLET MANIFOLD

By checking the pressure in the inlet manifold the

efficiency of an engine can be checked by making a

comparison with the information given in the FUEL

SETTING INFORMATION. This test is used

when there is a decrease of horsepower from the

engine, yet there is no real sign of a problem with the

engine.

The correct pressure for the inlet manifold is given

in the FUEL SETTING INFORMATION. Deve-

lopment of this information is done with these condi-

tions: 746.7 mm (29.4 in.) of mercury barometric

pressure, 29°C (85°F) outside air temperature and

35 API rated fuel. Any change from these conditions

can change the pressure in the inlet manifold. Out-

side air that has higher temperature and lower baro-

metric pressure than given above will cause a lower

horsepower and inlet manifold pressure measure-

ment, than given in that FUEL SETTING INFOR-

MATION. Outside air that has a lower temperature

and higher barometric pressure will cause a higher

horsepower

and

inlet

manifold

pressure

measurement.

A difference in fuel rating will also change horse-

power and the pressure in the inlet manifold. If the

fuel is rated above 35 API, pressure in the inlet

manifold can be less than given in the FUEL SET-

TING INFORMATION. If the fuel is rated below

35 API, the pressure in the inlet manifold can be

more than given in the FUEL SETTING INFOR-

MATION. BE SURE THAT THE AIR INLET

AND EXHAUST DO NOT HAVE A RESTRIC-

TION WHEN MAKING A CHECK OF PRES-

SURE IN THE INLET MANIFOLD.

Use the 6V3150 Engine Pressure Group to check

the pressure in the inlet manifold.

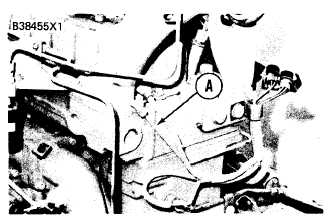

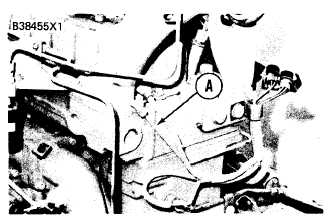

L O C A T I O N T O C H E C K I N L E T M A N I F O L D P R E S S U RE

A. Fitting.

Remove fitting (A) on inlet air pipe to measure

inlet manifold pressure.

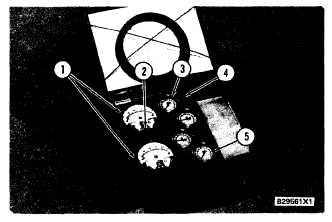

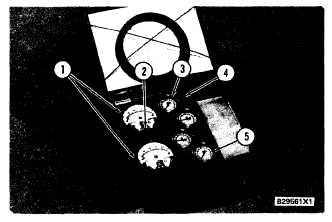

This tool group has a gauge to read pressure in

the inlet manifold. Special Instruction Form No.

SEHS7851 is with the tool group and gives in-

formation on the use of the group.

6 V 3 1 5 0 E N G I N E P R E S S U R E G R O U P

1 . D i f f e r e n t i a l p r e s s u r e g a u g e s . 2 . Z e r o a d j u s t m e nt

screw. 3. Pressure gauge 0 to 1100 kPa (0 to 160 psi). 4.

Pressure tap. 5. Pressure gauge 0 to 415 kPa (0 to 60 psi).

MEASUREMENT OF EXHAUST

TEMPERATURES

Use the 1P3060 Pyrometer Group to check ex-

haust temperature. Special Instruction Form No.

SMHS7179 is with the tool group and gives instruc-

tions for the test procedure.

4-26.1/4-26.2 (blank)