F U E L S Y S T E M

TM 5-3805-258-24-1

T E S T I N G A N D A D J U S T I NG

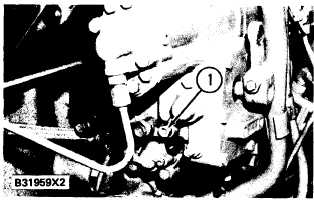

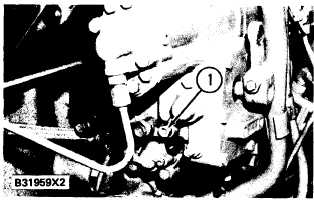

DASHPOT SCREW ADJUSTMENT

(TYPICAL EXAMPLE)

1. Dashpot adjustment screw.

1. Turn dashpot adjustment screw (1) in (clock-

wise) until it stops.

2. Turn dashpot adjustment screw out (counter-

clockwise) 1/2 ± 1/4 turn.

Checking Balance Point

The balance point for the engine is:

1.

2.

3.

4.

At 20 rpm higher than full load speed.

The point where the power adjustment screw is

against the load stop.

The point where the engine has the most horse-

power output.

The point where an increase in load on the engine

puts-the engine in a lug condition (a condition in

which a small increase in load makes the engine

speed get much less).

Procedure for Checking Balance Point

NOTE: It is important, to the correct operation of

the transmission, that the BALANCE POINT is

adjusted to the correct specifications.

NOTE: The rack setting must be correct before

an adjustment is made to the balance point.

1. Connect a tachometer which has good accuracy

to the tachometer drive.

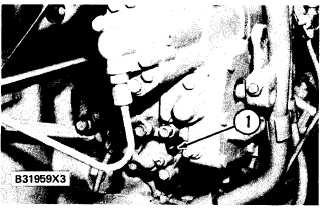

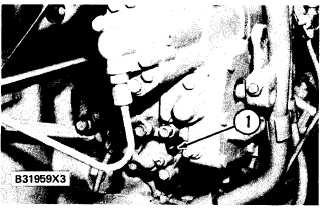

2. Connect a continuity light to the brass terminal

screw (1) on the rear of the governor. Connect

the other end of the light to a place on the fuel

system which is a good electrical ground.

3.

4.

5.

6.

7.

8.

9.

10.

11.

TERMINAL LOCATION

(TYPICAL EXAMPLE)

1. Brass terminal screw.

Start the engine.

With the engine at operating conditions, run the

engine at high idle.

Make a record of the speed of the engine at high

idle.

Add load on the engine slowly until the contin-

uity light just comes on. This is the balance

point.

Make a record of the speed at the balance point.

Repeat Step 6 several times to make sure that

the recording is correct.

Stop engine. Make a comparison of the records

from Steps 5 and 7 with the information given

in the FUEL SETTING INFORMATION.

If the full load speed is not correct; adjust the

HIGH IDLE speed to make a change in the full

load speed.

If the high idle speed is out of tolerance and the

full load speed is correct, look for a weak gover-

nor spring or the wrong governor spring. Both

the full load speed and the high idle speed must

be in the tolerance given in-the FUEL SET-

TING INFORMATION.

4-25