TM 5-3805-258-24-1

A I R S Y S T E M A N D B R A K E S

T E S T I N G A N D A D J U S T I NG

EMERGENCY AND PARKING

BRAKE ADJUSTMENT

E M E R G E N C Y A N D P A R K I N G B R A KE

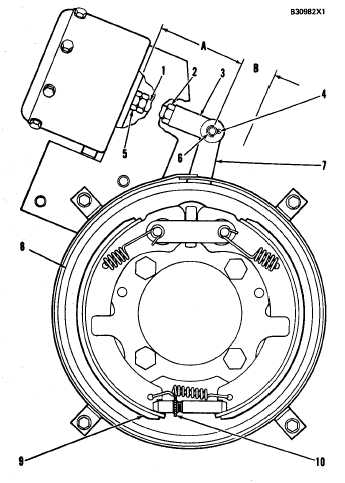

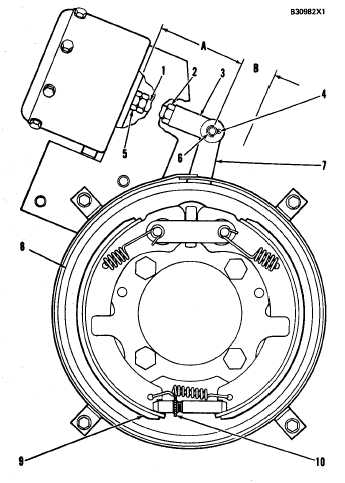

1. Rod. 2. Nut. 3. Rod end. 4. Cotter. 5. Nut. 6. Pin. 7.

L e v e r . 8 . D r u m . 9 . S h o e ( t w o ) . 1 0 . S t a r w h e e l . A . D i -

mension from face of mounting bracket to center of pin (6).

B. Stroke of lever (7).

WARNING

Make reference to WARNING on first page of

AIR SYSTEM AND BRAKES TESTING AND AD-

JUSTING section,.

1.

2.

3.

4.

5.

6.

7.

8.

9.

Start the engine and let the air pressure go up to

operating range.

Move the control knob for the parking brake to

OFF (brake released) position. Stop the engine.

Remove cotter (4) and pin (6). Remove lever (7)

from its shaft.

Turn starwheel (10) to get a clearance between

shoes (9) and drum (8) of..

(.010 ± .005 in.)

Loosen nut (2) and turn rod

mension (A) of . . . . . . . . . . . . . . . . . . . .

install lever (7), pin (6) and

0.25 ± 0.12 mm

end (3) to get di-

100.0 mm (3.94 in.)

cotter (4).

Usc nut (5) to turn rod (1) until free movement

between rod end (3) and lever (7) is removed.

Tighten nut (2).

Move the control knob for the parking brake to

ON (brake engaged) position and check the

stroke [distance (B)]. Do Steps 1 through 8

again if distance (B) is more than 19.0 mm (.75

in.)

NOTE: The parking brake is adjusted correctly if the

machine can not be moved in first speed forward.

4-66