H Y D R A U L I C

S Y S T E M

TM 5-3805-258-24-1

T E S T I N G

A N D

A D J U S T I N G

Lift, lower, dump and tilt back the bucket several

times.

1.

2.

3.

4.

Watch the cylinders as they are extended and

retracted. Movement must be smooth and

regular.

Listen for noise from the pump.

Listen for the sound of the relief valves. They

must not open except when the cylinders are

fully extended or retracted, when the bucket is

empty.

Watch the operation of the bucket positioner

and lift kickouts.

The lift control lever has detents in the RAISE and

FLOAT positions.

The tilt control lever has a detent in the TILT

BACK position (only when the bucket is between full

dump and the bucket angle to dig).

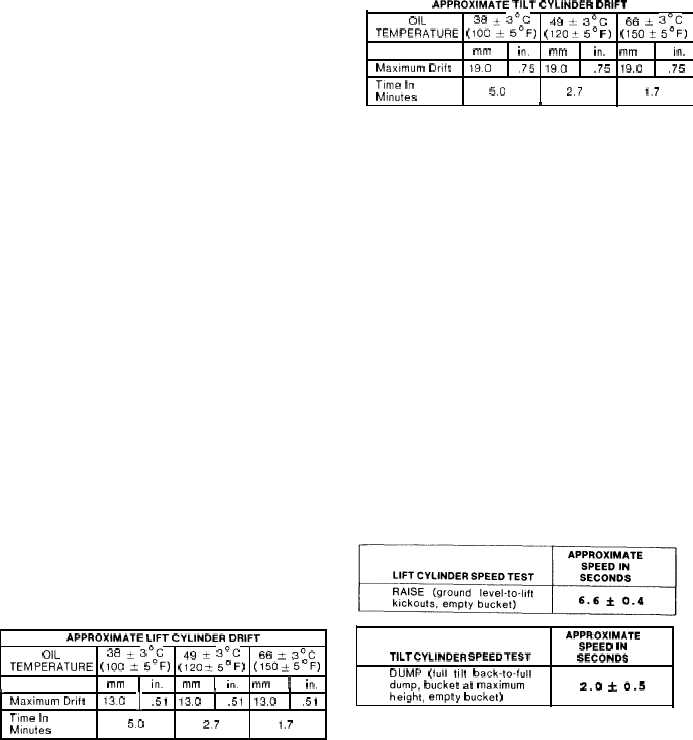

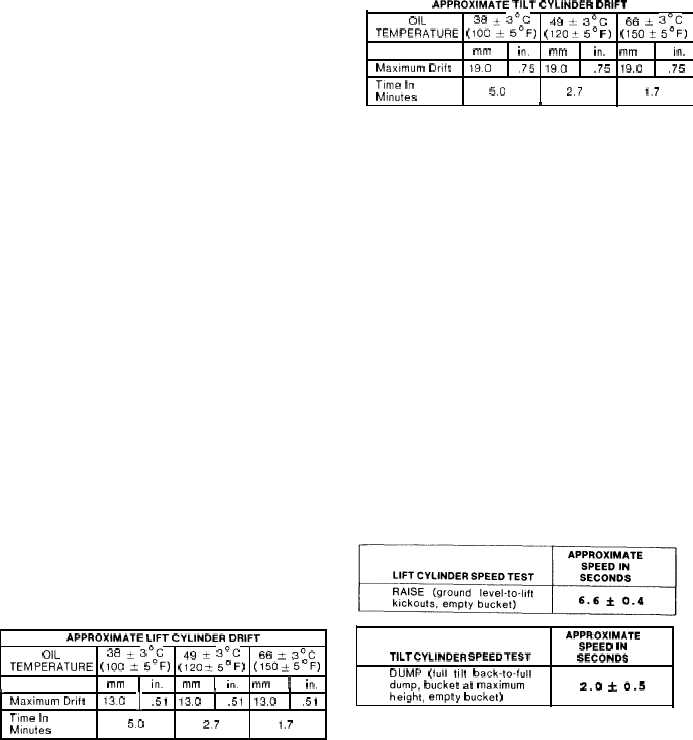

Lift And Tilt Cylinder Drift Tests

The drift rates will change with different condi-

tions of the hydraulic components as well as with the

operation, the type of bucket (empty or loaded),

hydraulic oil temperature, etc.

The values shown are for an empty bucket. Before

measuring drift on the cylinder rod, the cylinders

must be extended at least five times. Check the oil

temperature.

To check the lift circuit, lift the bucket to maxi-

mum height and move the control lever to the HOLD

position. Measure the distance (and check the time)

that the cylinders retract, with the chart.

NOTE: The drift distances in the charts are for new

machines.

APPROXIMATE LIFT CYLINDER DRIFT

OIL

38 ~ 3°C

49 f 3c’c

66 * 3°c

TEMPERATURE

(100 i 5°F)

(120 f5° F)

(150 L 5°F)

mm

in.

mm

in.

mm

I

in,

L

1

1

Maximum Drift

13.0

1

.51

13.0

.51

13.0

.51

Time In

Minutes

5.0

2,7

1.7

To check the tilt circuit, lift the bucket to maxi-

mum height, and move the lift control lever to the

HOLD position. Activate the tilt circuit until the

bucket is at the angle to dig (almost level) and move

the tilt control lever to the HOLD position. Measure

the distance (and check the time) that the cylinder

retracts, with the chart.

I

APPROXIMATE TILT CYLINDER DRIFT

OIL

38 ~ 3°C

49 f 3°c

66 * B“c

TEMPERATURE

(100 Y 5°F)

(120 f5° F)

(150t5° F)

mm

in.

mm

in.

mm

in.

Maximum Drift

19.0

.75

19.0

.75

19.0

.75

Time In

Minutes

5.0

2.7

1.7

1

I

I

If the cylinder drift is too much:

1. Check the make-up valves in the lift and tilt

control valve.

2. Check the condition of the valve spools in the lift

and tilt control valve.

3. Check the piston seals in the cylinders.

Attachment Cylinder Drift

The attachment cylinders will drift in the close or

lower direction because of an orifice (to the tank) in

the line from the rod end of the attachment

cylinders.

Lift And Tilt Cylinder Speed Tests

Start and run the engine at high idle rpm. Lift and

lower the lift arms again and again to get an increase

in the temperature of the hydraulic oil.

The oil in the system must be SAE 10 and at a

temperature of 65 ± 3°C (150 ± 5°F) to get accur-

ate test results. All speed tests are made with the

engine at high idle. The speeds in the following chart

are those of machine equipped with a general pur-

pose bucket.

APPROXIMATE

SPEED IN

TILT CYLINDER SPEED TEST

SECONDS

DUMP (full tilt back-to-full

dump, bucket at maximum

height, empty bucket)

2.0 * 0.5

If the travel times are not correct:

1. Check the pump efficiency.

2. Check the setting of the relief valves.

3. Check the make-up valves in the lift and tilt

control valve.

4. Check the valve spools in the lift and tilt control

valve.

5. Check the piston seals in the cylinders.

4-69