H Y D R A U L I C

S Y S T E M

TM 5-3805-258-24-1

T E S T I N G

A N D

A D J U S T I N G

HYDRAULIC SYSTEM

WARNING

Hydraulic oil, under pressure that can be

higher than 34500 kPa (5000 psi) can remain in

the hydraulic system on this machine after the

engine and pump have been stopped. Sudden

movement of the machine or release of oil

under pressure can cause injury to persons on

or near the machine. To prevent possible in-

jury, do the procedure that follows before test-

ing and adjusting the hydraulic system:

1.

2.

3.

4.

5.

6.

7.

8.

9.

Move the machine to a smooth horizontal loca-

tion. Move away from working machines and

personnel.

Permit only one operator on the machine. Keep

all other personnel either away from the

machine or in view of the operator.

Activate the parking brake. With the engine run-

ning, put the bucket flat on the ground. When

the bucket is raised for tests or adjustments, be

sure that the bucket has correct support and the

bucket is in the full dump position. The lift cir-

cuit has high oil pressure when the lift arms

raise the front of the machine. DO NOT STOP

THE ENGINE with the front of the machine off

of the ground.

Install the anti-pivot link.

Make sure all hydraulic pressure is released

before any fitting, hose or component is

loosened, tightened, removed or adjusted.

Move the lift control lever to FLOAT position.

Shut off the engine.

Move the lift control lever to the HOLD position.

Carefully loosen the filler cap on the hydraulic

tank to release the pressure.

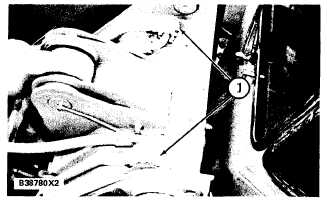

10. Carefully loosen plugs (1) at the rear of the tilt

cylinder. When the oil from the loosened plugs

stops, tighten the two plugs.

NOTE: To release the pressure in the attachment

cylinders, carefully loosen two large plugs near

11. Tighten the filler cap on the hydraulic tank.

12. The pressure in the system has now been

released and lines or components can be

removed.

R E A R O F T I L T C Y L I N D ER

1. Plugs.

During a diagnosis of the hydraulic system, re-

member that correct oil flow and pressure are neces-

sary for correct operation. The output of the pump

(oil flow) increases with an increase in engine speed

(rpm) and decreases when engine speed (rpm) is

decreased. Oil pressure is caused by resistance to the

flow of oil.

Visual checks and measurements are the first step

when troubleshooting a possible problem. Then do

the Operation Checks and last the Instrument Tests.

Use the 5S5123 Hydraulic Test Group, 6V4161

Hydraulic Test Group, a stop watch, a magnet, a

thermometer and a mm (inch) ruler for basic tests

to measure:

1.

2.

The pressure of the oil to open the relief valves

for the main and pilot systems and the relief

valves for the tilt circuits. Relief valve pressures

that are too low will cause a decrease in the lift

and the dig characteristics of the machine. Pres-

sures that are too high will cause a decrease in

the life of hoses and components.

Drift rates in the lift and tilt circuits: Circuit

drift is caused by a leakage past cylinder pistons,

O-ring seals in the control valves, check valves or

make-up valves that do not seat correctly or poor

adjustment or fit in the control valves.

plugs (1) at the top of the loader frame. When the oil

from the loosened plugs stops, tighten the two large

plugs.

4-67