A I R S Y S T E M A N D B R A K E S

CONTROL VALVE FOR EMERGENCY

AND PARKING BRAKE

T o o l s N e e d e d : 0 t o 1 3 8 0 k P a ( 0 t o 2 0 0 p s i ) G a u g e .

Make reference to WARNING on first page of

AIR SYSTEM AND BRAKES TESTING AND AD-

JUSTING section.

WARNING

1.

2.

3.

4.

5.

6.

7.

8.

9.

L O C A T I O N T O I N S T A L L G A U GE

1. Drain valve of the air reservoir.

Install a 0 to 1380 kPa (0 to 200 psi) gauge in

drain valve (1) of the air reservoir.

Start the engine and let the pressure go up to

cutout pressure 725 ± 14 kPa (105 ± 2 psi).

With the control knob for the emergency and

parking brake in the OFF position (pushed in),

stop the engine.

Push one of the brake pedals rapidly several

times, until the control knob automatically

moves to the ON position.

Read the pressure on the gauge.

The correct pressure to automatically engage the

parking brake is 275 ± 35 kPa (40 ± 5 psi). If the

pressure on the gauge is not correct, the opera-

tion of the control valve for the secondary and

parking brake is not correct.

Disassemble the control valve and check for

worn or damaged parts.

If this does not correct the problem, install a new

valve.

Remove the gauge.

TM 5-3805-258-24-1

T E S T I N G

A N D

A D J U S T I N G

BRAKE CONTROL VALVES

The application of the wheel brakes must be the

same when either of the brake pedals are pushed.

When the left pedal is pushed, the transmission is

disengaged and the brakes are activated. When the

right pedal is pushed, only the brakes are activated.

This is the only difference between the operation of

these pedals.

If the operation of the wheel brakes is not the

same between the two pedals, there is a failure in

one of the control valves. Repair or replace the

brake control valve that has failed.

LEAKAGE IN HYDRAULIC CIRCUIT

T o o l s N e e d e d : 9 S 7 6 9 2 I n v e r t e d F l a r e C o n n e c t o r .

1 / 8 i n . P i p e P l u g .

T a p e m e a s u r e .

Make reference to WARNING on first page of

AIR SYSTEM AND BRAKES TESTING AND AD-

JUSTING section.

Problem

Loss of brake fluid from the reservoirs can be

caused by one or more of the following reasons.

1. Leakage at hose or tube connections or leakage

through damaged hoses or tubes.

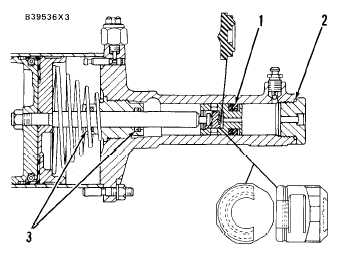

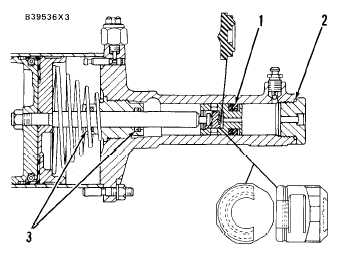

2. Leakage around seals (1), (2) or (3) of the mas-

ter cylinder. This leakage can be caused by in-

correct installation or a cut or damaged seal.

M A S T E R C Y L I N D E R

1. Seal. 2. Seal. 3. Seals.

4-61