TM 5-3805-258-24-1

H Y D R A U L I C

S Y S T E M

11. Lift the lift arms as high as they will go. Do

Steps 5 and 6 again only this time move the lift

control lever to RAISE position. The pressure

on the gauge must be the same as in Step 6.

Pilot Pressure For Lower And Float

12.

13.

14.

15.

To check pressure for the lower stem, remove

the swivel tee from hose assembly (3) and in-

stall it between the hose assembly and elbow

at connector (10).

Lower the bucket to the ground. Do Steps 5 and

6 again, only this time move the lift control lever

to FLOAT position. The pressure on the gauge

must be the same as in Step 6.

Release the pressure in the hydraulic system and

remove the test equipment.

Remove the air in the pilot system. See PROCE-

DURE TO REMOVE AIR FROM PILOT

SYSTEM.

PROCEDURE TO REMOVE AIR FROM PILOT

SYSTEM

WARNING

Make reference to WARNING on first page of

LOADER HYDRAULIC SYSTEM TESTING AND

ADJUSTING section. Air in the pilot system can

cause an extremely dangerous condition. The

bucket can drop whenever the engine stops or

is shut off. If this condition happens the proce-

dure that follows should correct the problem.

TOOIS Needed:

6V4161 Hydraulic Test Group

5H4018 Cover

5H4019 Covers (Two)

F R O N T O F L O A D E R F R A M E

1. Hose assembly to rod end of tilt cylinder. 2. Bleed screw

for tilt back operation. 3. Bleed screw for raise operation.

4-72

T E S T I N G

A N D

A D J U S T I N G

NOTE: Loose oil line connections and hoses or lines

that have oil leakage will let air into the hydraulic

system.

1.

2.

3.

4.

Disconnect hose assembly (1) from the tilt

cylinder.

Install a 5H4019 Cover between the hose assem-

bly and the tilt cylinder. Connect hose assembly

(1) to the tilt cylinder.

Install a 5H4018 Cover between hose assem-

blies (6) and (7) and their blocks.

Start and run the engine at low idle.

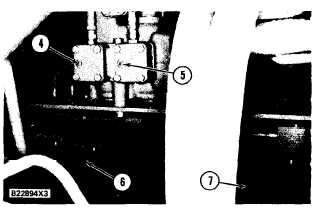

B A C K O F L I F T A N D T I L T C O N T R O L V A L VE

( T Y P I C A L )

4. Bleed screw for lower and float operations. 5. Bleed

screw for dump operation. 6. Hose assembly to rod end

of left lift cylinder. 7. Hose assembly to rod end of right

lift cylinder.

5.

6.

7.

8.

9.

10.

11.

12.

13.

Move the tilt control lever to TILT BACK

position.

Loosen (open) bleed screw (2). Keep it open

until there is a constant flow of oil (no air bub-

bles) from bleed screw (2).

Tighten (close) bleed screw (2). Release the tilt

control lever.

Move the tilt control lever to DUMP position.

Open bleed screw (5). Keep it open until there is

a constant flow of oil (no air bubbles) from the

bleed screw.

Close bleed screw (5). Release the tilt control

lever.

Move the lift control lever to RAISE position.

Open bleed screw (3). Keep it open until there is

a constant flow of oil from the bleed screw.

Close bleed screw (3). Move the lift control lever

to HOLD.