S I N G L E C Y L I N D E R

A I R C O M P R E S S O R

TM 5-3805-258-24-1

T E S T I N G A N D A D J U S T I N G

TESTING AND ADJUSTING

The air pressure gauge will show low air pressure

in the system when air system checks or tests are

needed. Air system checks are needed if the needle

in the air pressure gauge keeps moving when the

components in the air system are not being used.

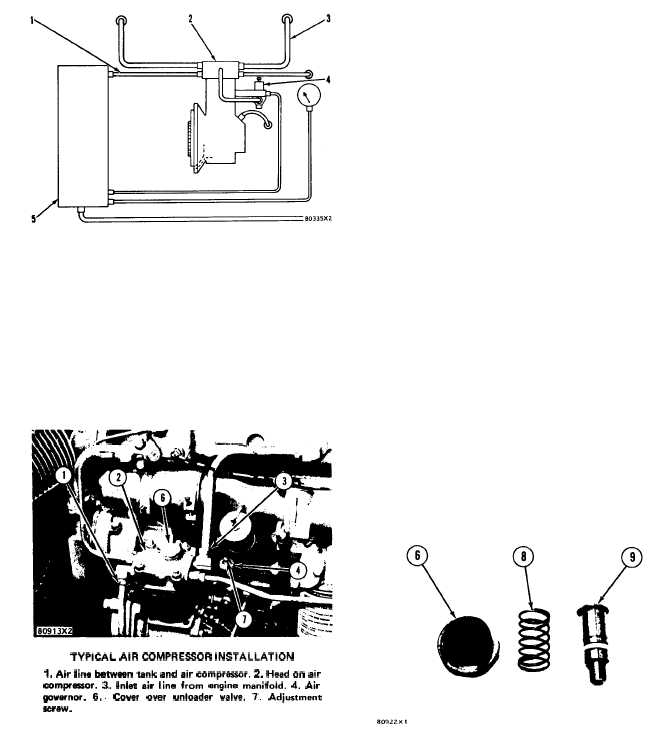

AIR SYSTEM SCHEMATIC

1. Air line between tank and air compressor. 2. Head for air

compressor. 3. Inlet air line from engine manifold. 4. Air

governor. 5. Air tank.

The complete air system, including the com-

ponents in the air system, must be checked for any

air leaks. The air lines must have no breaks and all

of the air line connections must be tight and have

no air leaks. If all of the air leaks have been

stopped and the air pressure gauge still has indi-

cations of low air pressure further tests are needed.

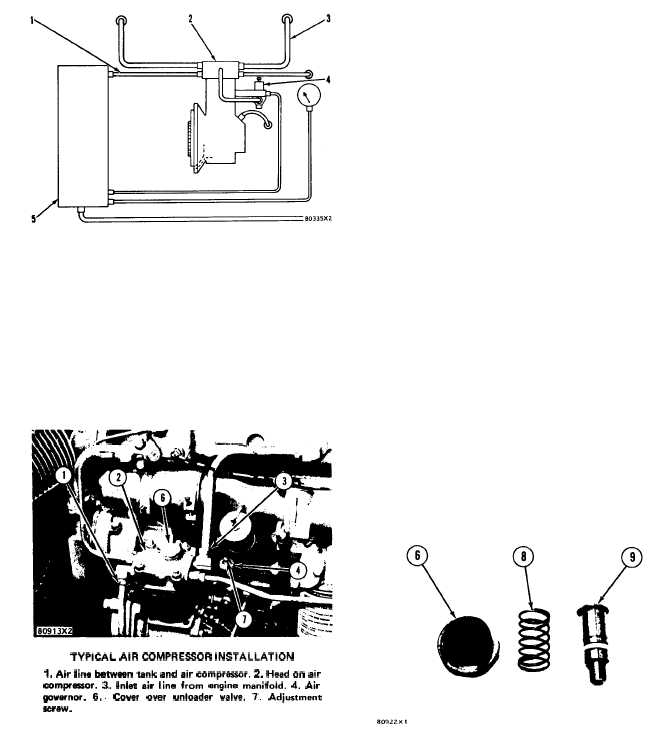

TYPICAL AIR COMPRESSOR INSTALLATION

1. Air line between tank and air compressor. 2. Head on air

com~eaaor. 3. Inlet air line from angine manifold. 4. Air

@vernor. 6.. Cover over unloader valve. 7. Adjustment

Screw.

Stop the engine and let all of the air out of the

tank (5) and the air system. Disconnect line (1)

from the cylinder head (2) to the air tank.

4 - 81

Start the engine and let it run for a minute. With

the engine running hold a white card approxi-

mately 2 in. (50.8 mm) from the opening in the

head (2), where air line (1) was disconnected but

for no more than 10 seconds. A large area of oil on

the card is an indication of wear either in the bore

of the liner or the piston rings (and piston). A little

oil in fine drops is an indication of correct lubri-

cation. If the card test shows no wear, connect air

line (1) and let the air compressor fill the air tank

until the air pressure gauge will not indicate any

more pressure.

Run the engine at low idle speed and disconnect

air inlet line (3) from the cylinder head (2). With

the engine still running slow, hold, your hand close

to the opening in head (2) where air line (3) was

disconnected. If air can be felt coming from the

opening when the piston of the air compressor is

on the compression stroke, the inlet valve is not

closing. Either the unloader valve under cover (6) is

holding the inlet valve open or there is dirt on the

inlet valve holding it open. A broken spring under

the inlet valve will also keep the valve open.

The unloader valve can be cleaned by removing

cover (6), spring (8) and unloader valve (9). Clean

the unloader valve and the passage in the head

where the unloader valve fits.

Install the unloader valve, the spring and the

cover. Torque for cover (6) is 60 lb. ft. (8.3 mkg).

Start the engine and feel for air coming from the

opening where air line (3) was disconnected, if air

can be felt the inlet valve is not closing and the

head assembly must be removed to clean the inlet

valve.

UNLOADER VALVE

6. Cover. 8. Spring. 9. Unloader valve.